bean 2 cup coffee machine

The last project of the first semester consisted of a brief instructing us to design a coffee machine based on research gathered through secondary sources such as statistics companies like Mintel as well this being conjunctive with primary research such as user interaction analysis and customer persona. The concept was to be presented through the use of prototype mock Ups as well as being illustrated through solidworks.

Overall Idea of the machine

The machine chosen was a bean - to - cup coffee machine as the customer persona stated minimal effort was required to make a cup of coffee for the consumer corresponding with their morning routine.

The machine will have the selected functions and form to fit the selected market as well as the materials used reflecting it's price and overall quality.

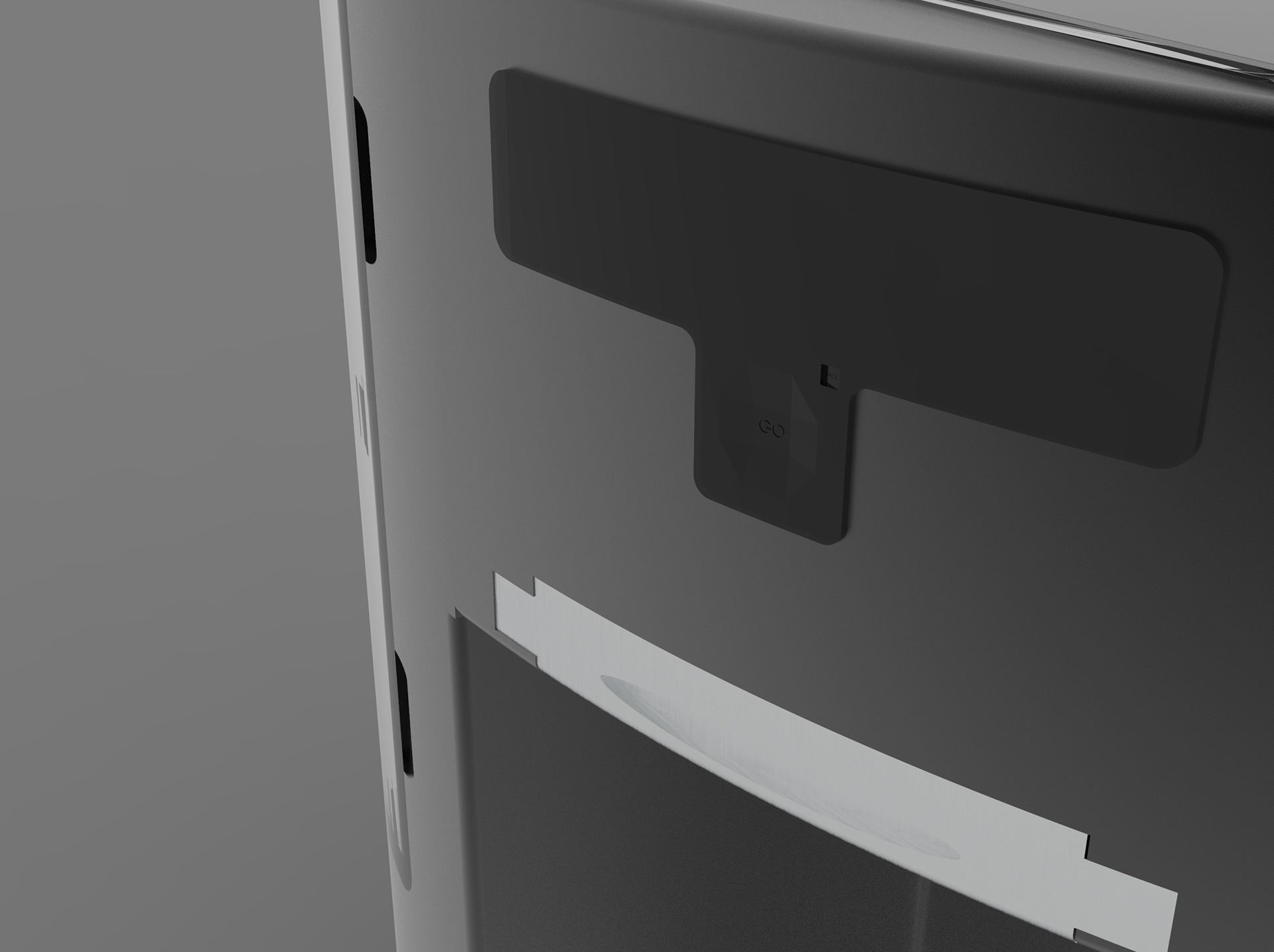

The machine will be controlled by a touch sensitive LCD Screen with GUI.

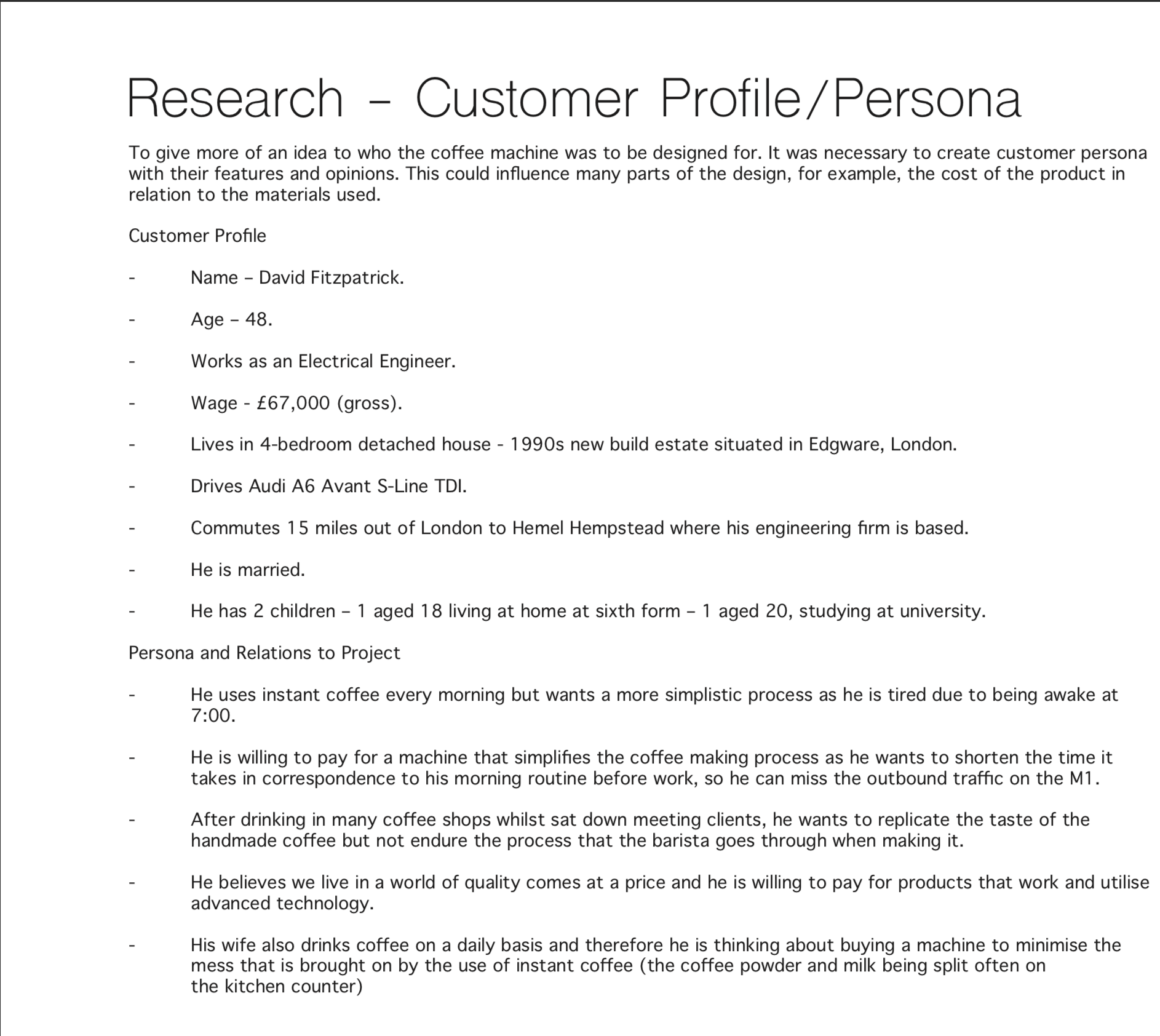

Above is a formulated customer persona. The main aspect of this driving the direction of the design in terms of its form and overall functionality in regards to touch points and material finishes. It also proved to ensure the project had firm grounding in the selected market.

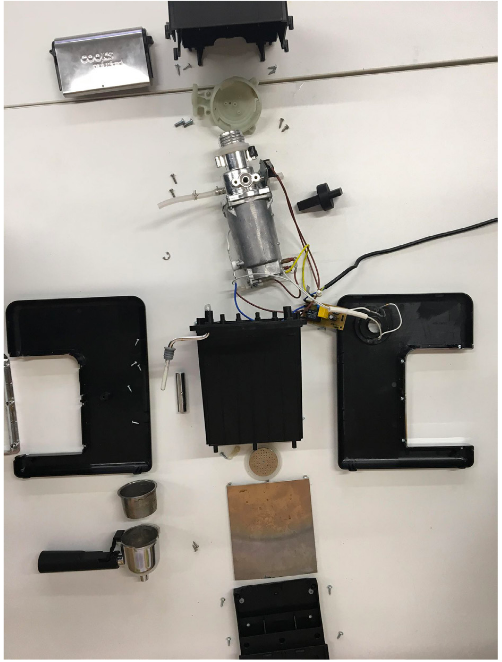

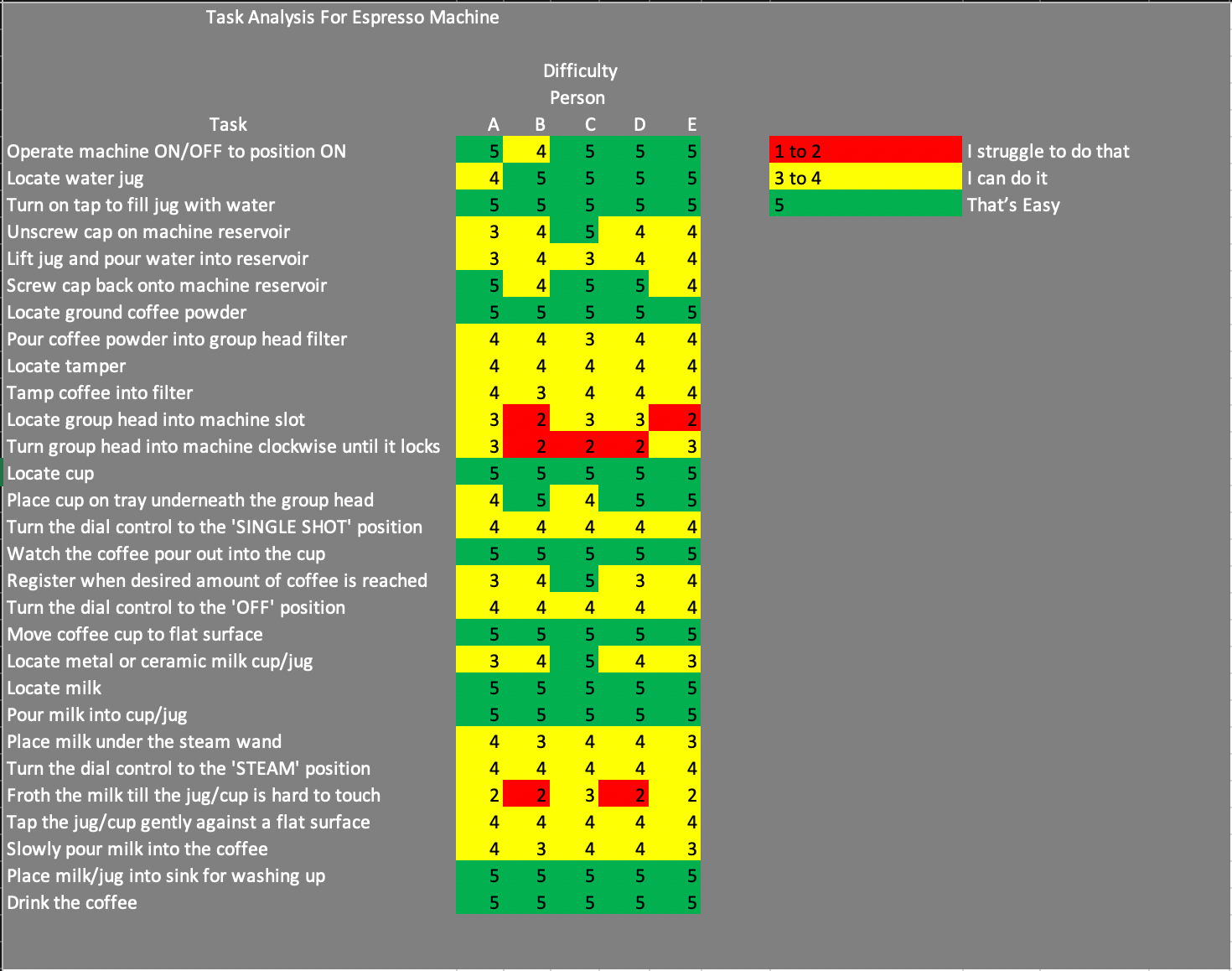

Other forms of provisional research included reverse engineering of espresso coffee machine and a task analysis for the said machine. These mainly drove insight to whether existing components and technology could be reused whilst the task analysis provide issue led development of functions to make the machine address all of the problems highighted in red.

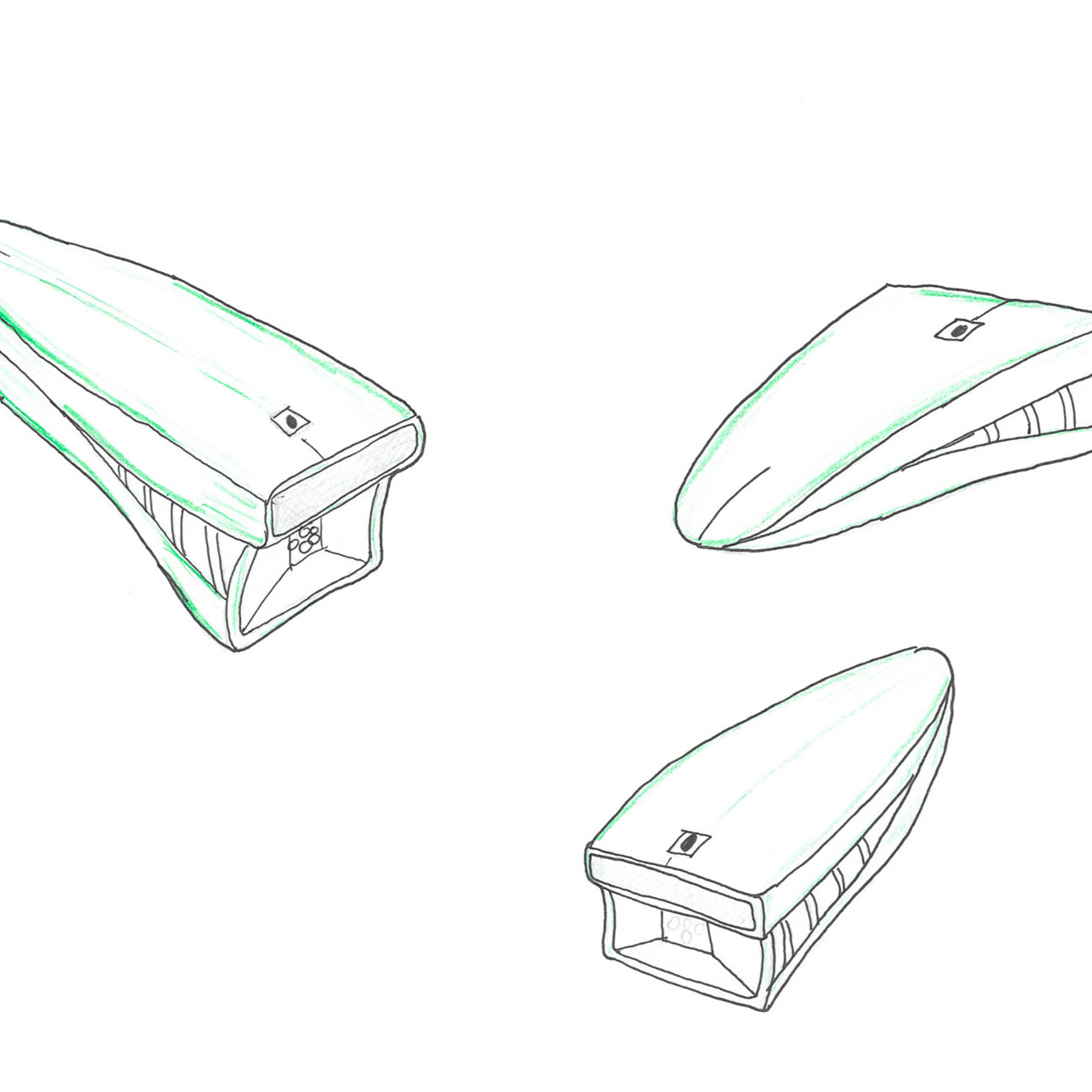

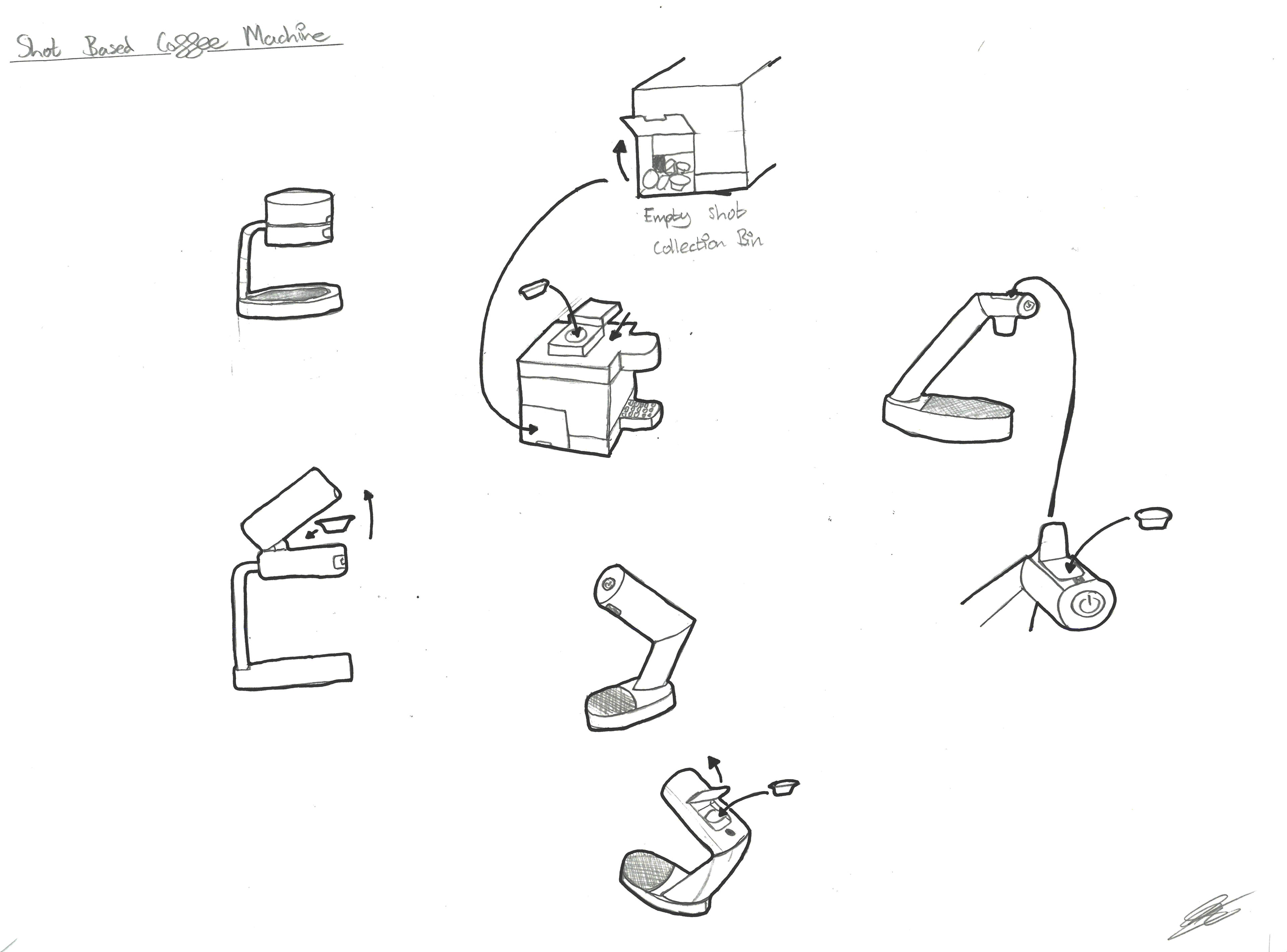

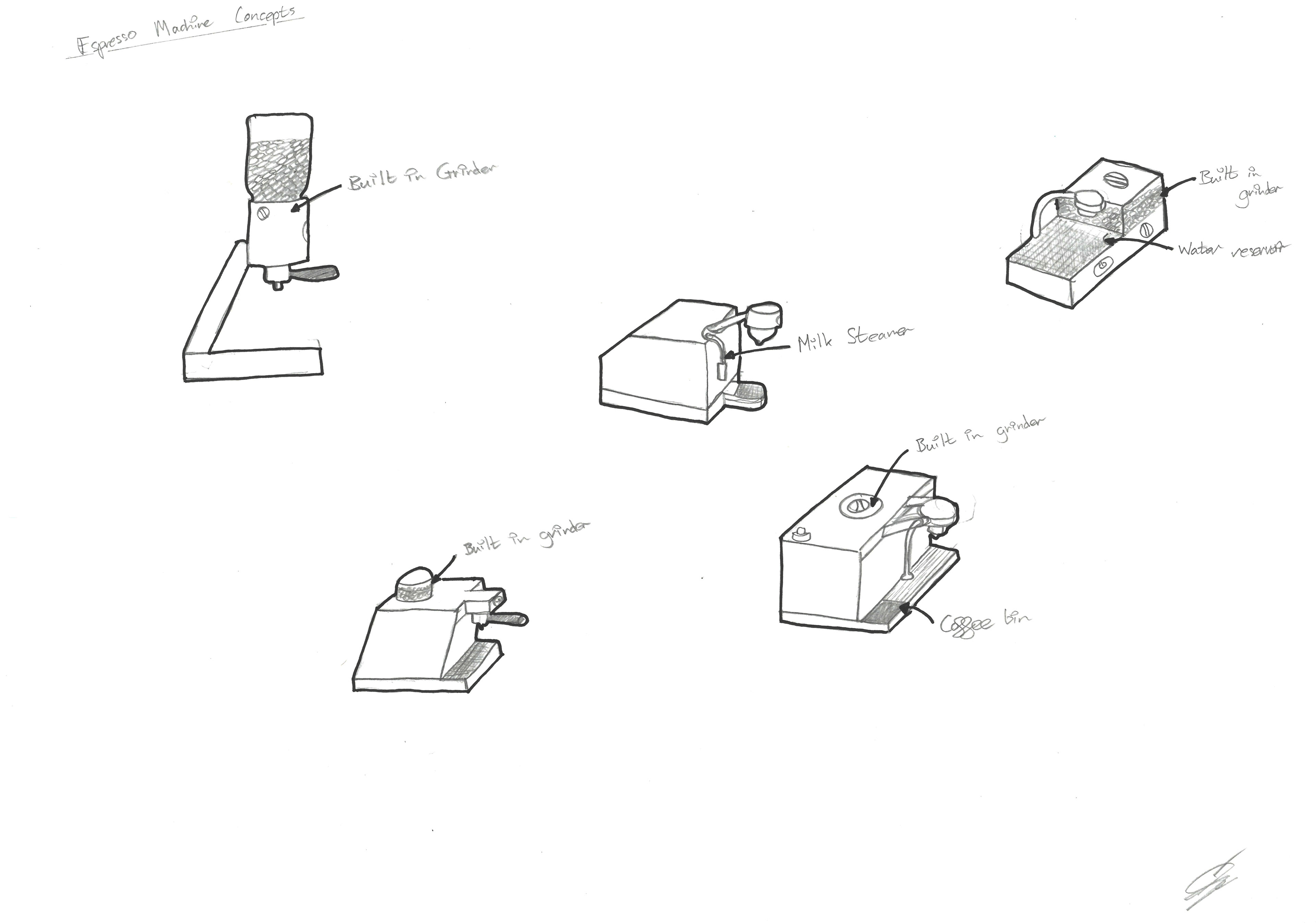

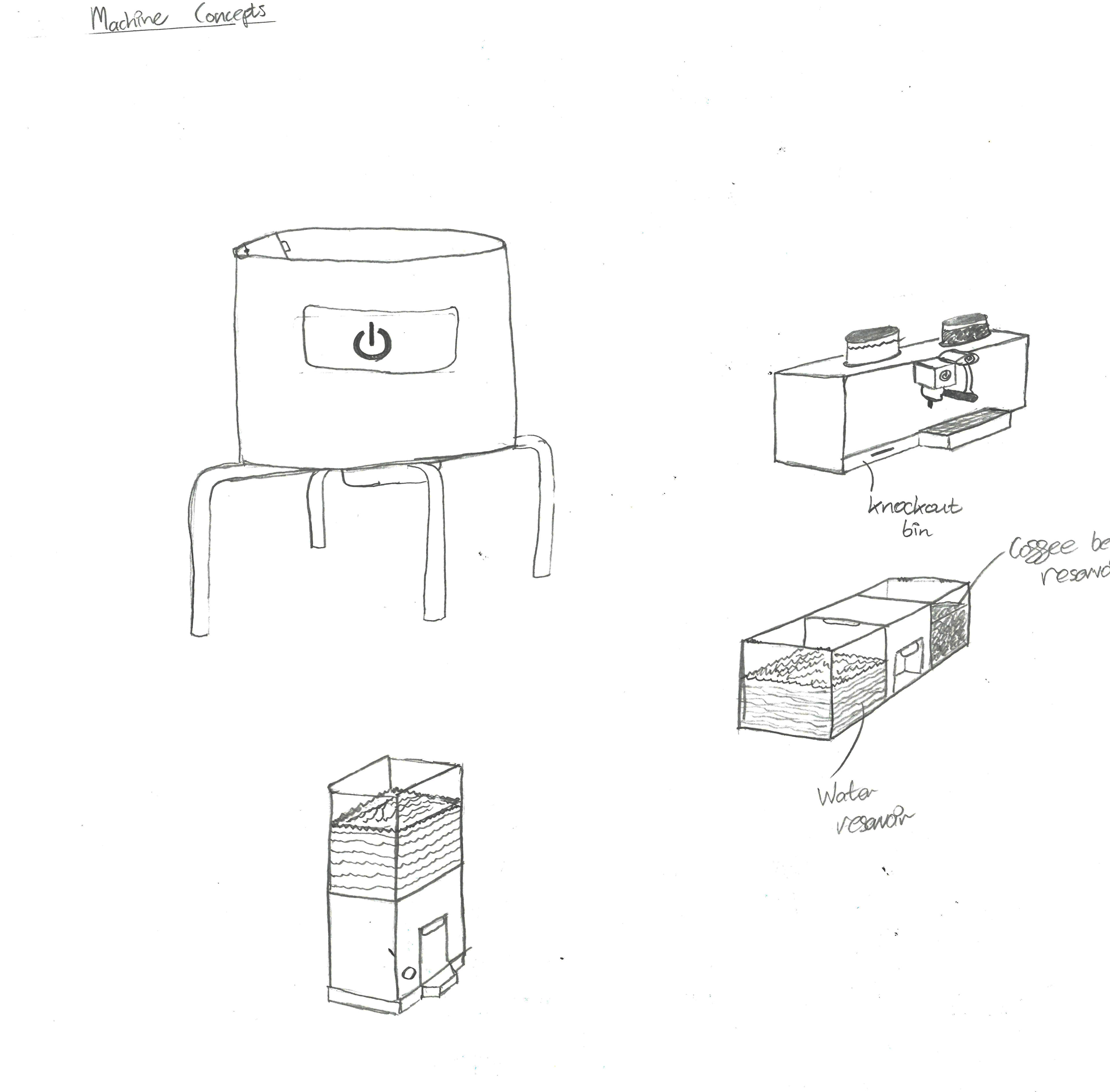

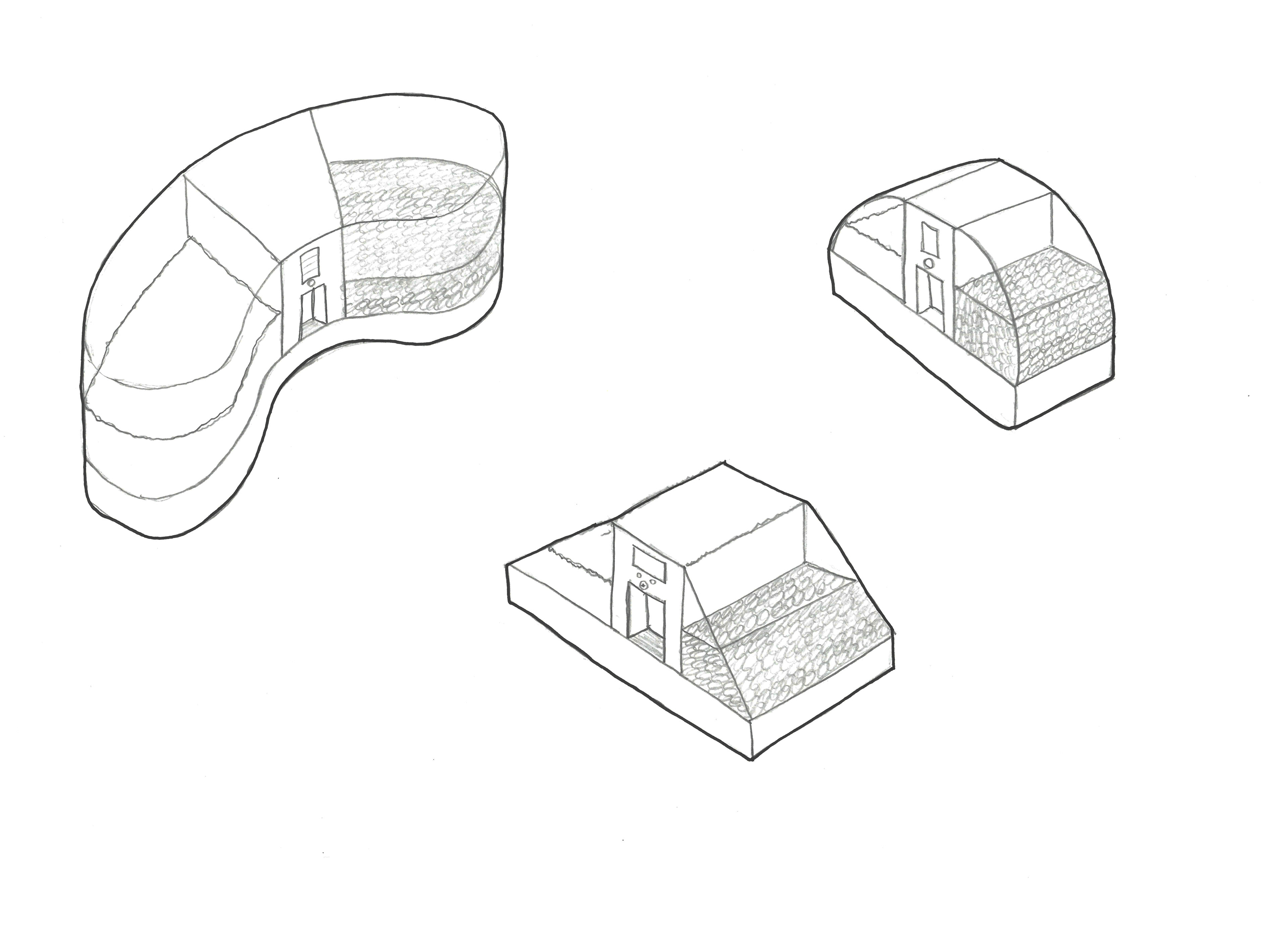

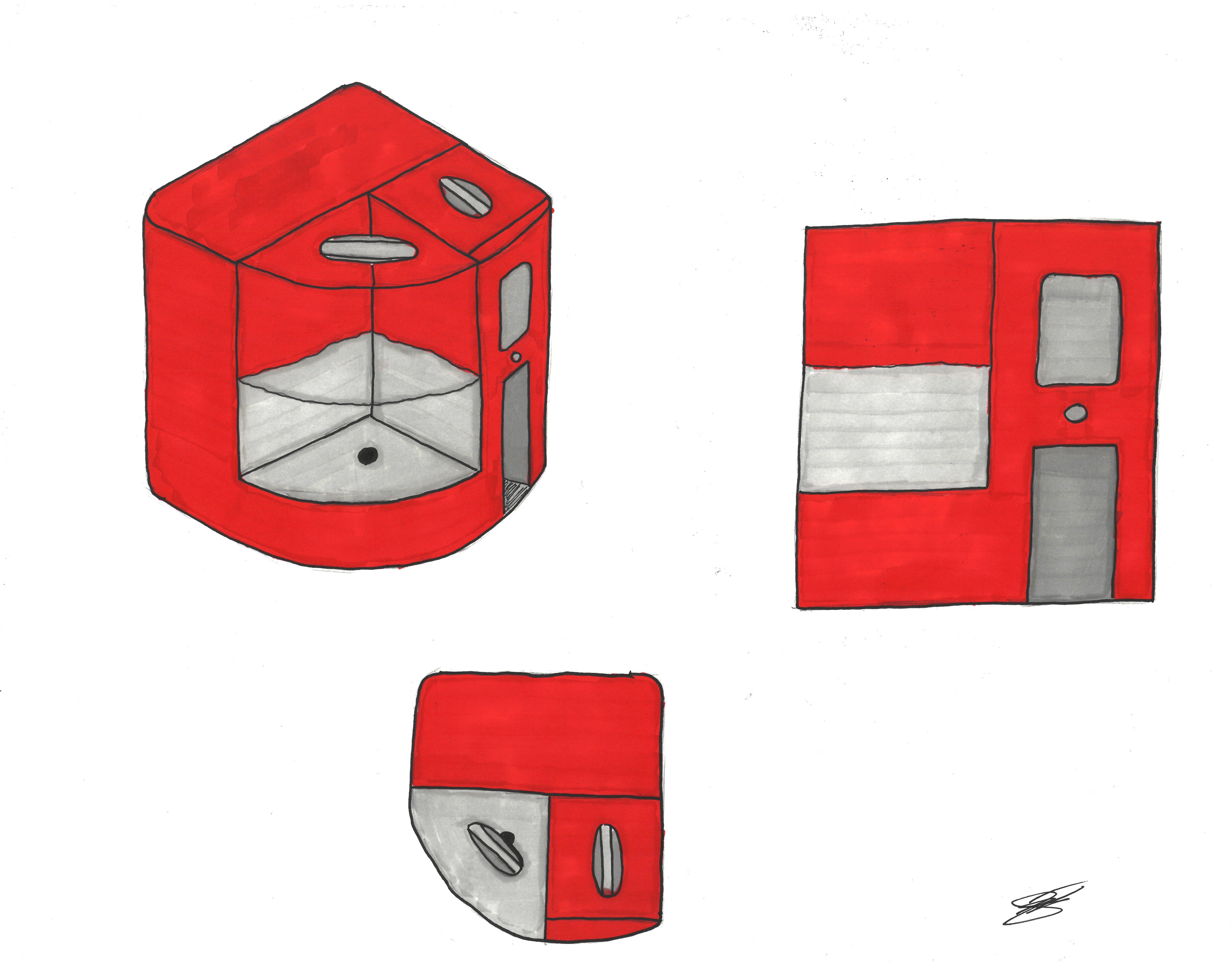

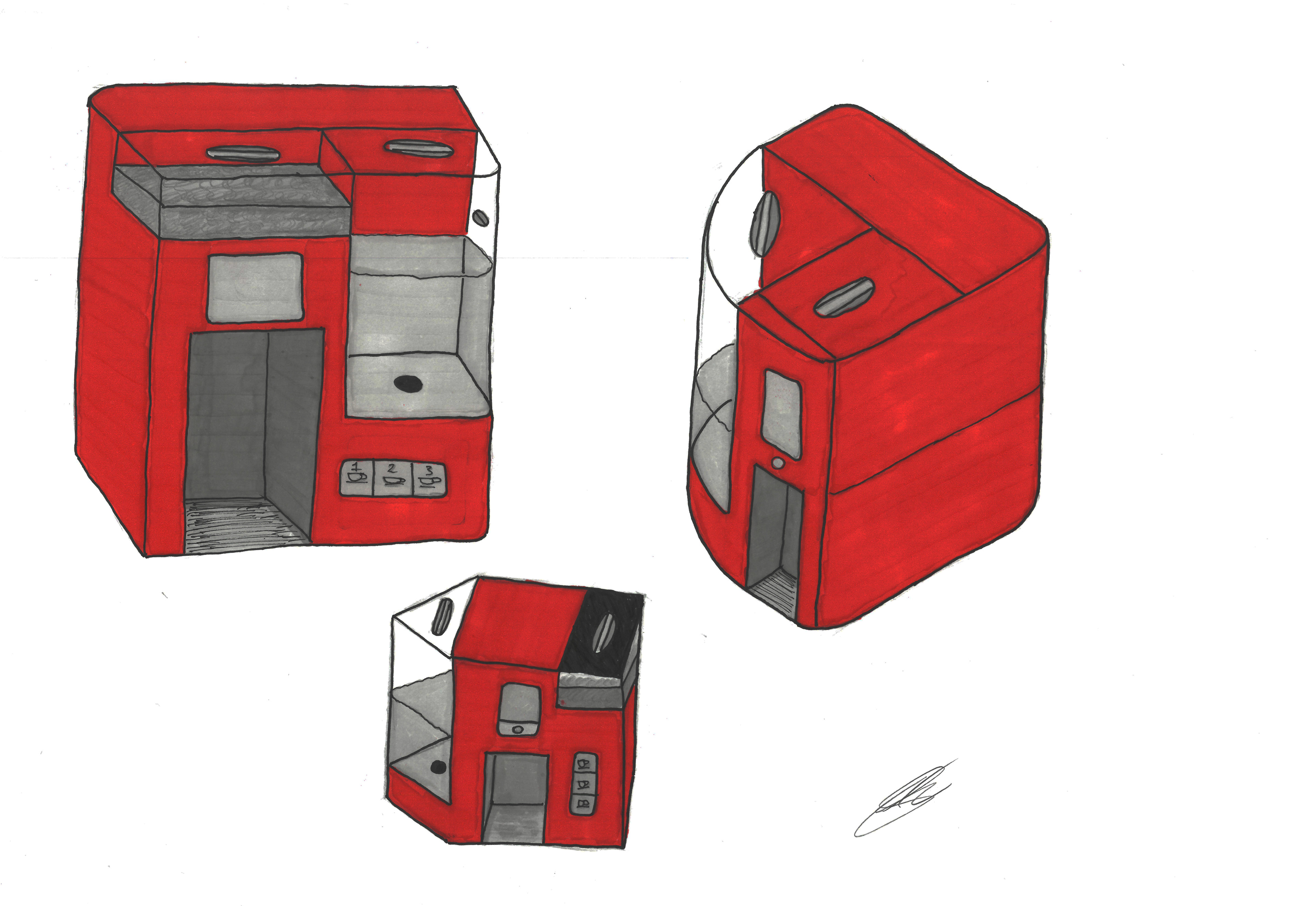

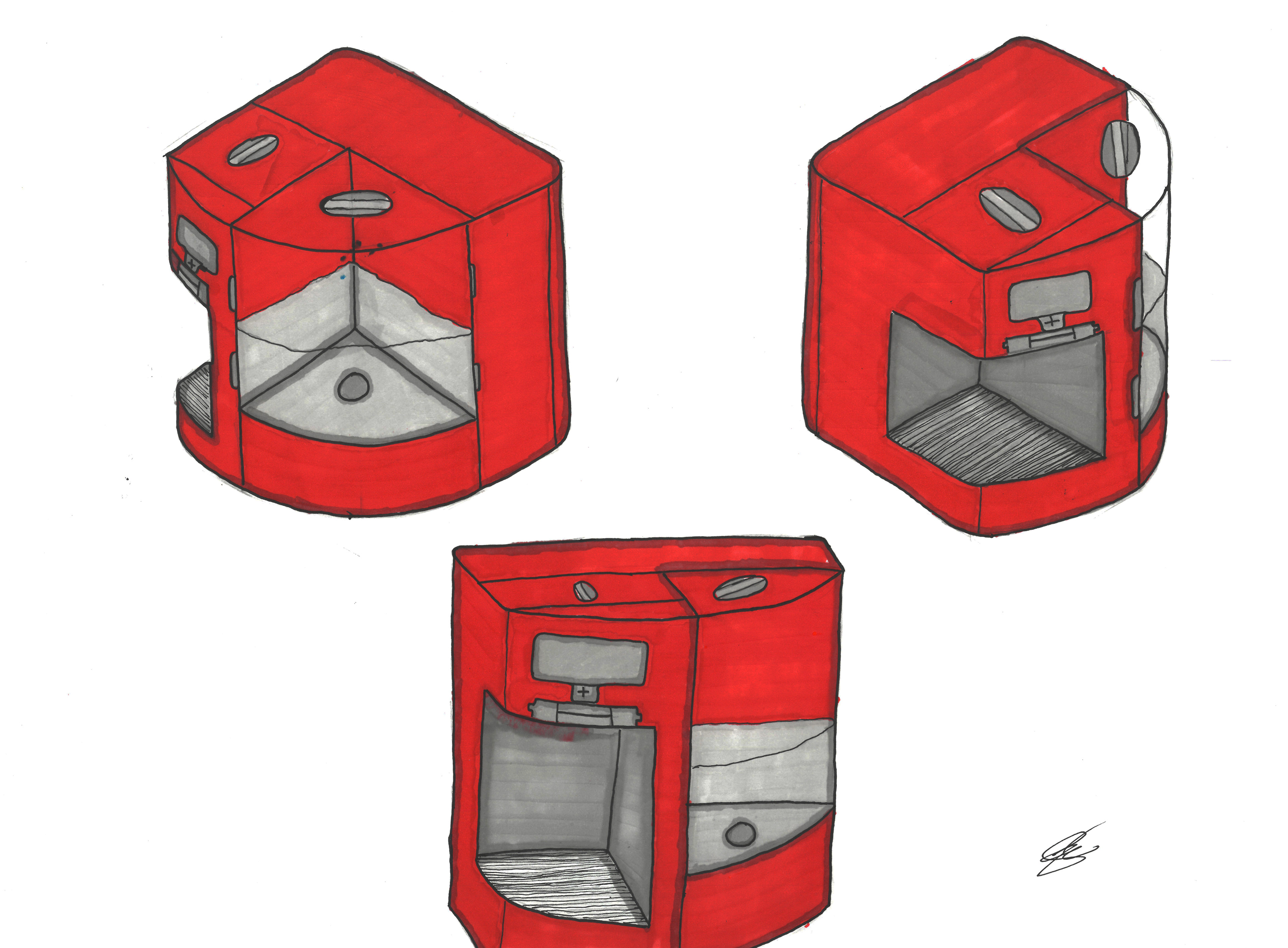

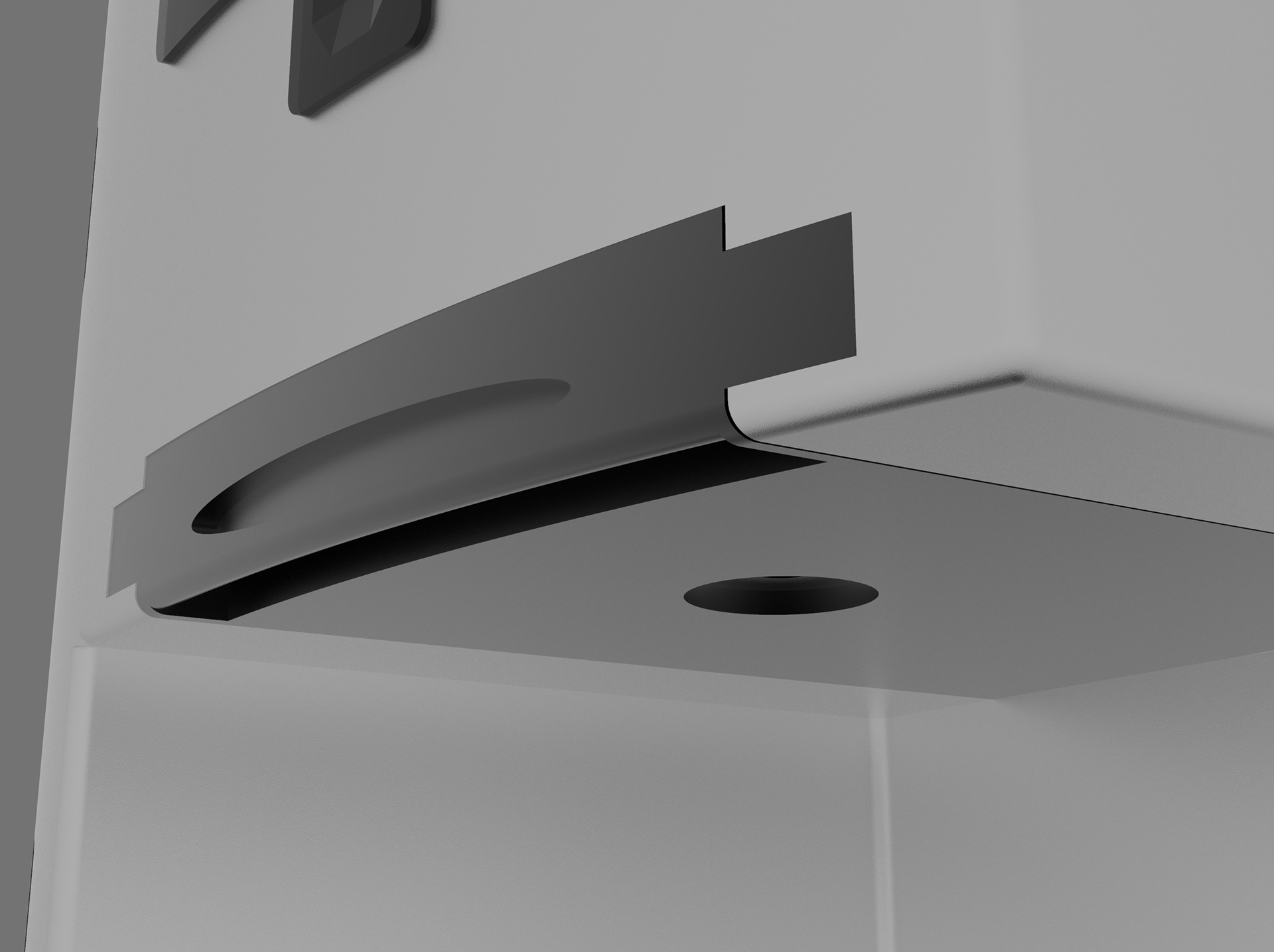

The development of the machine was done through iterations of forms. These being very basic and playing about with the location of the different components formed around an espresso machine and the direction followed towards a water dispenser style tank and LCD screen for the different options and the bean hopper being located directly above the grinder. The way of dispensing the spent coffee was also ideated in terms of having a pull out drawer in the front of the machine below the display.

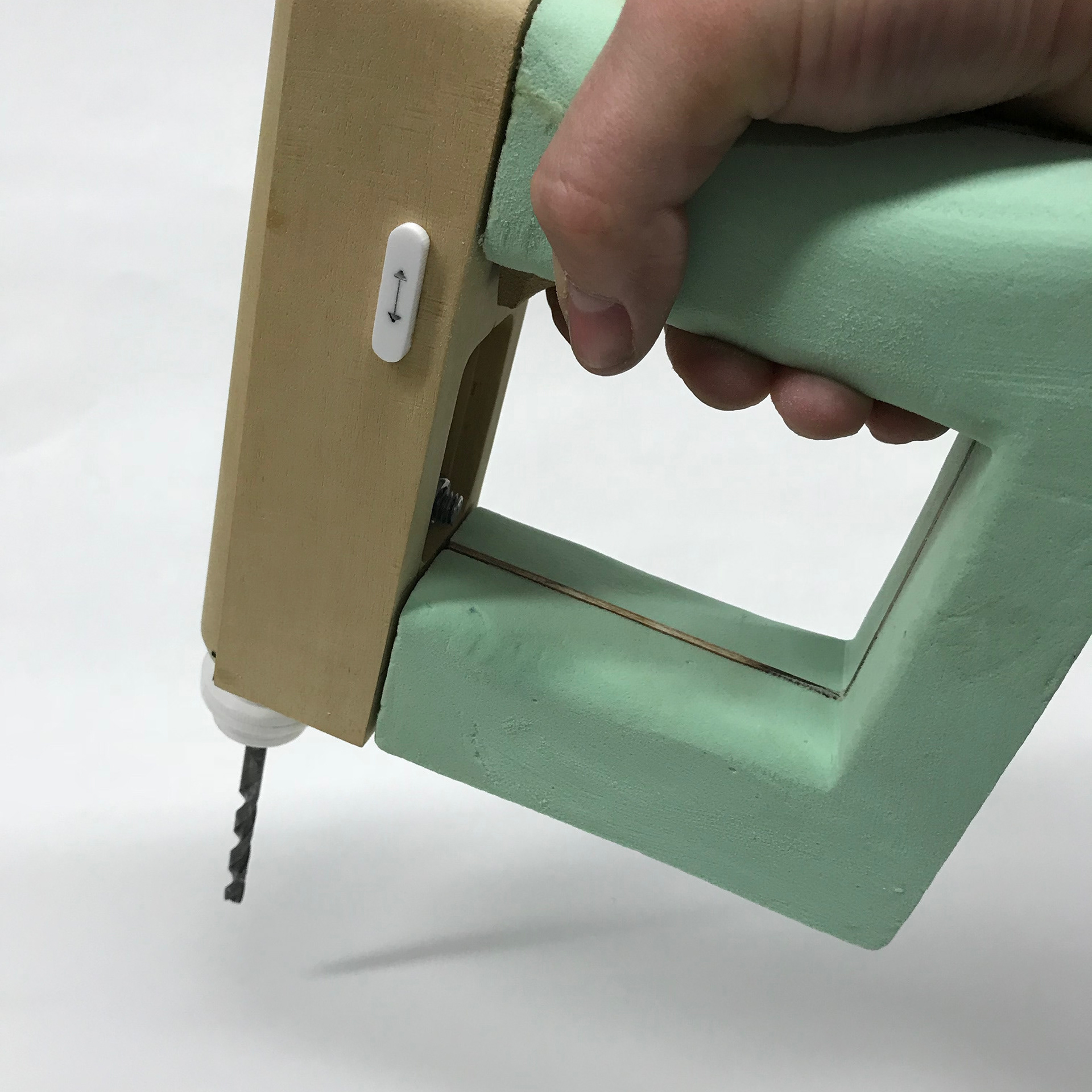

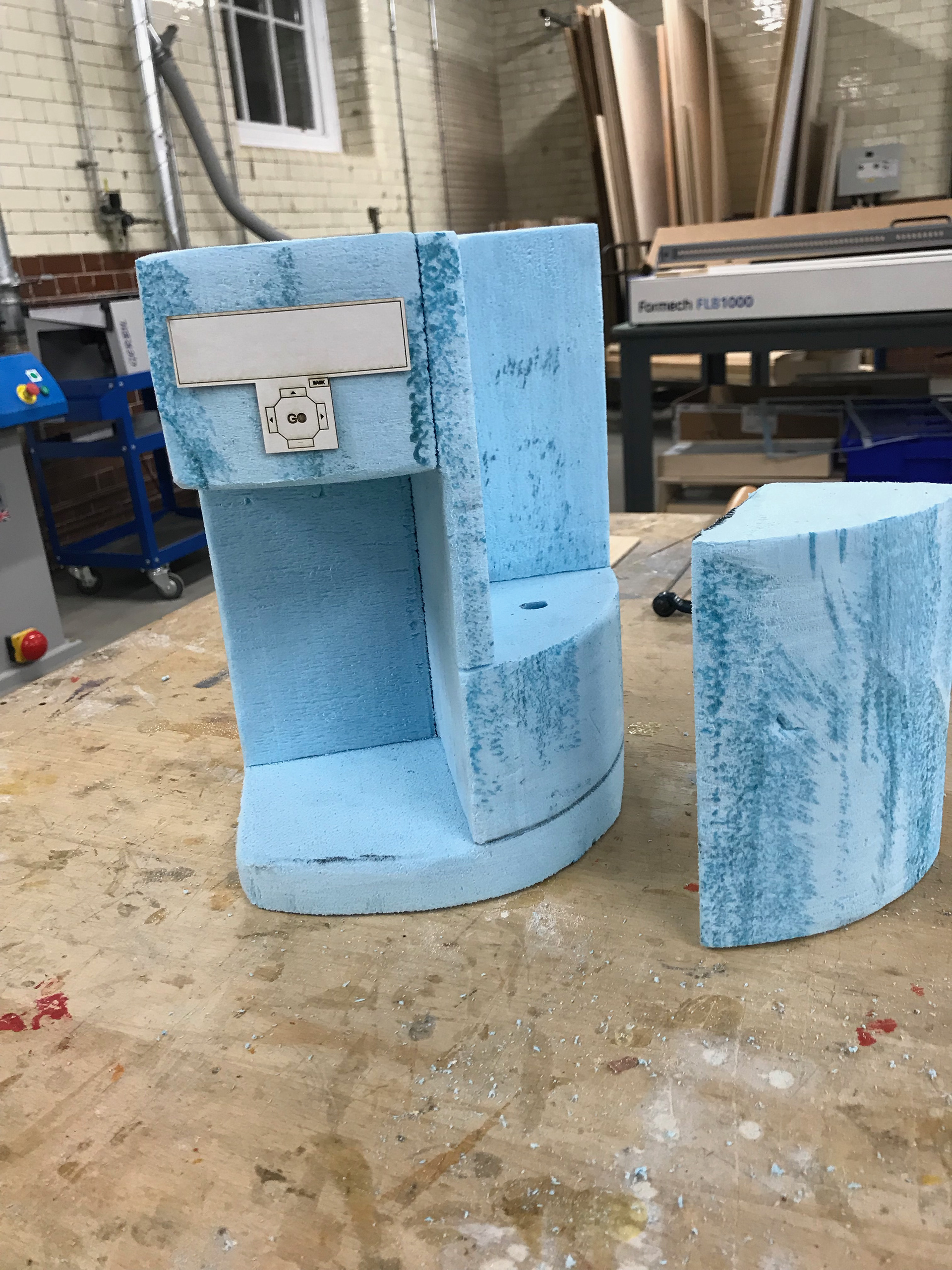

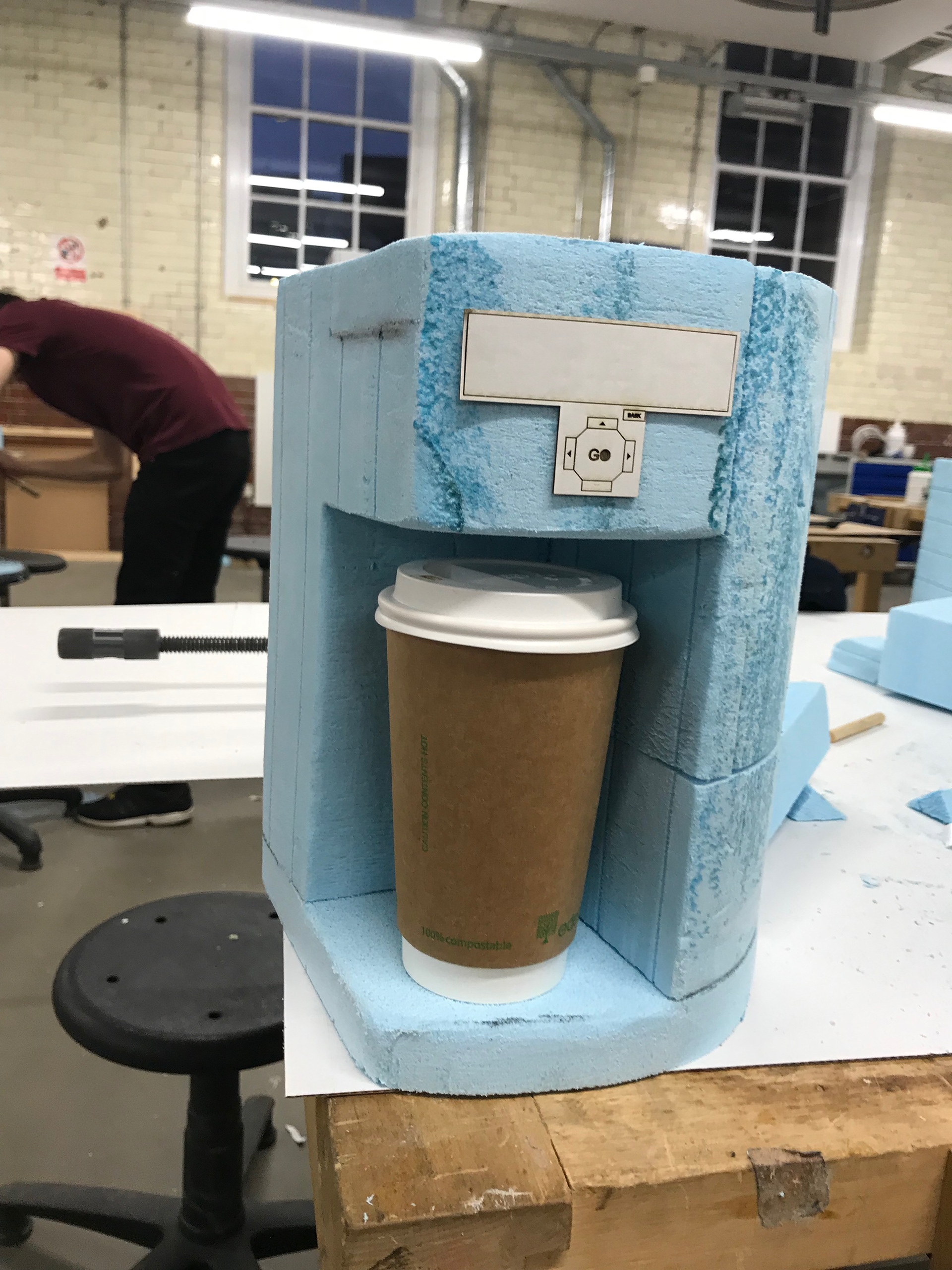

As the design was currently 2D. A model was made out of blue foam to prove size and scale of the overall machine and the products touchpoints. This proved important as three iterations of the machine were prototyped arriving at the size pictured above.

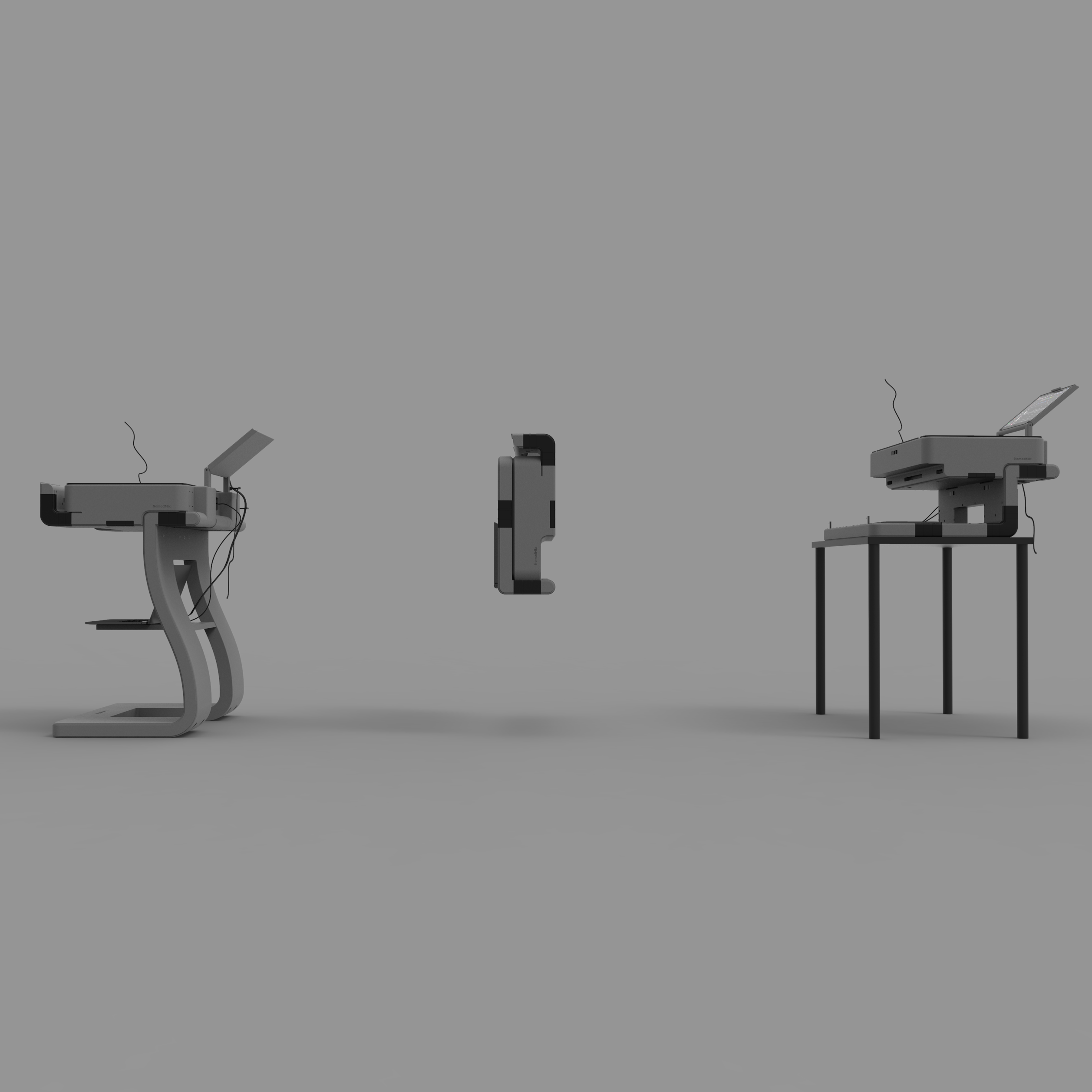

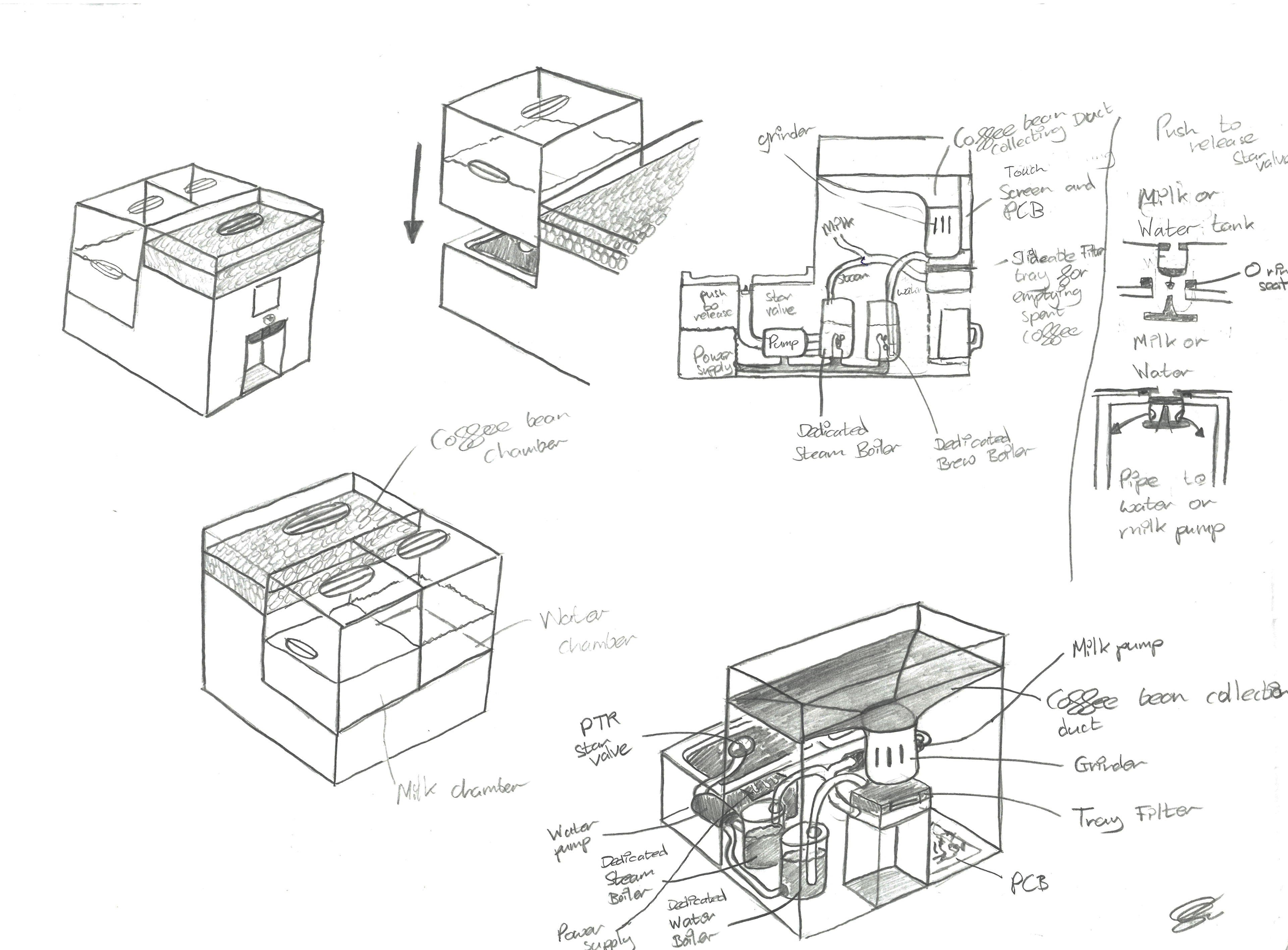

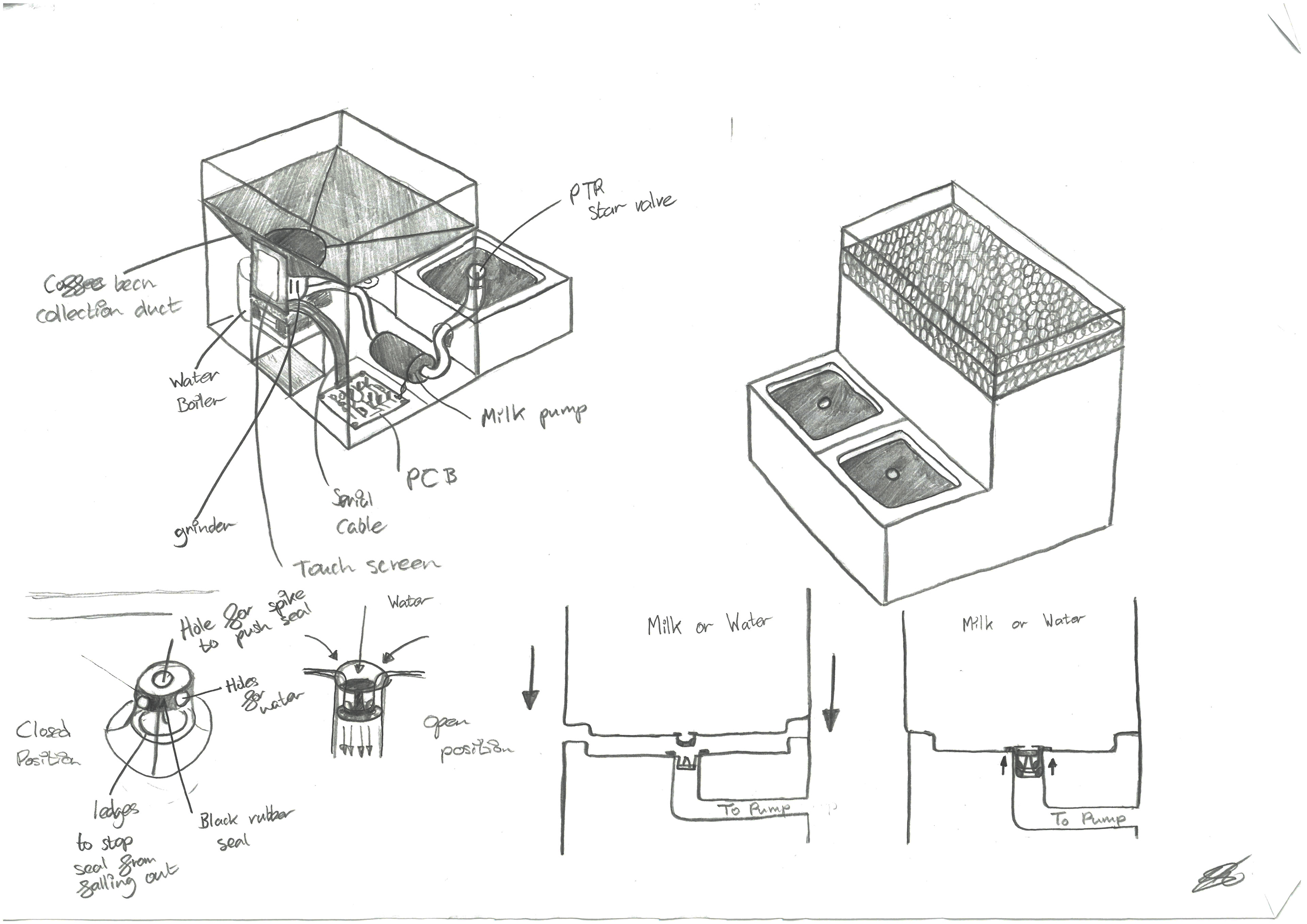

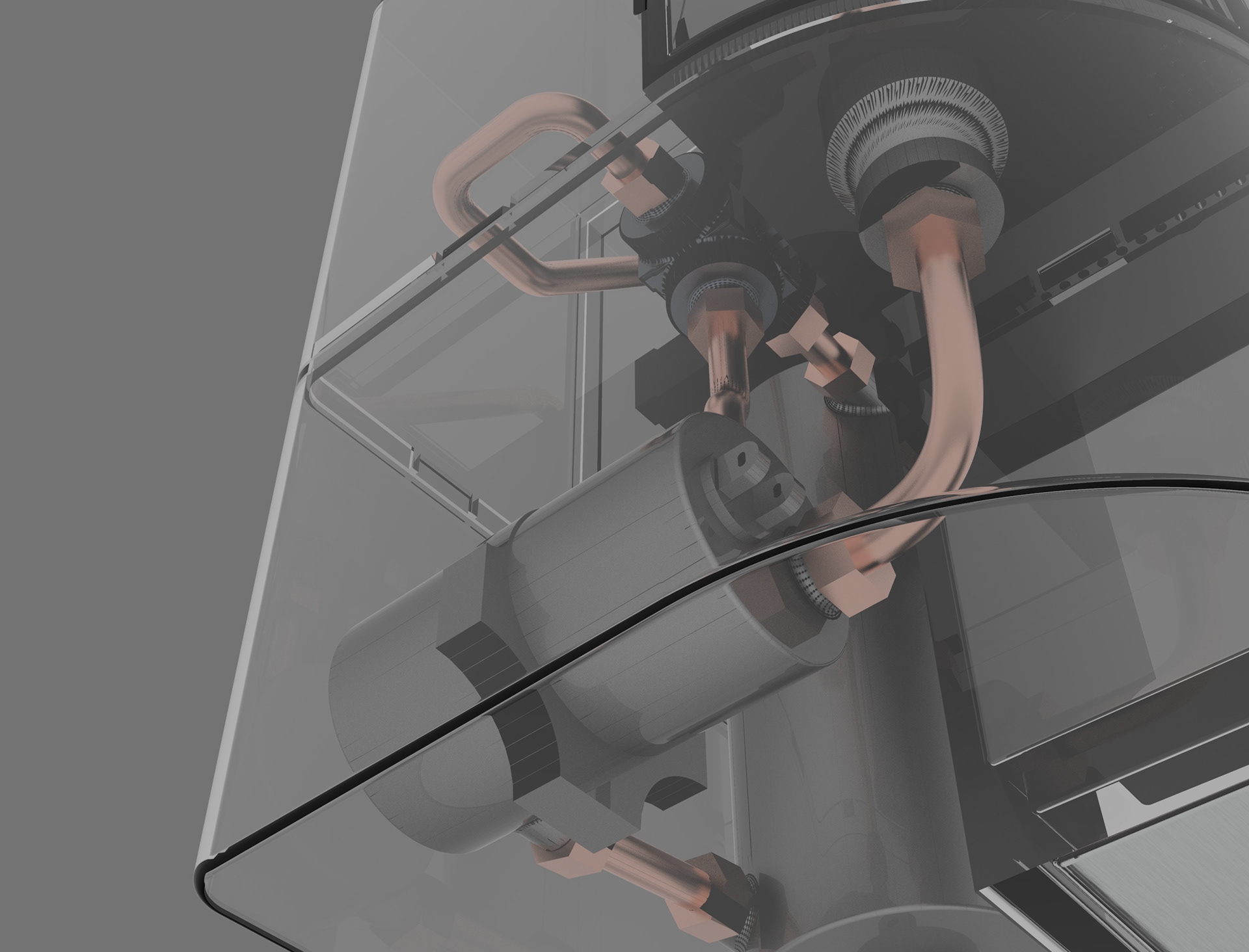

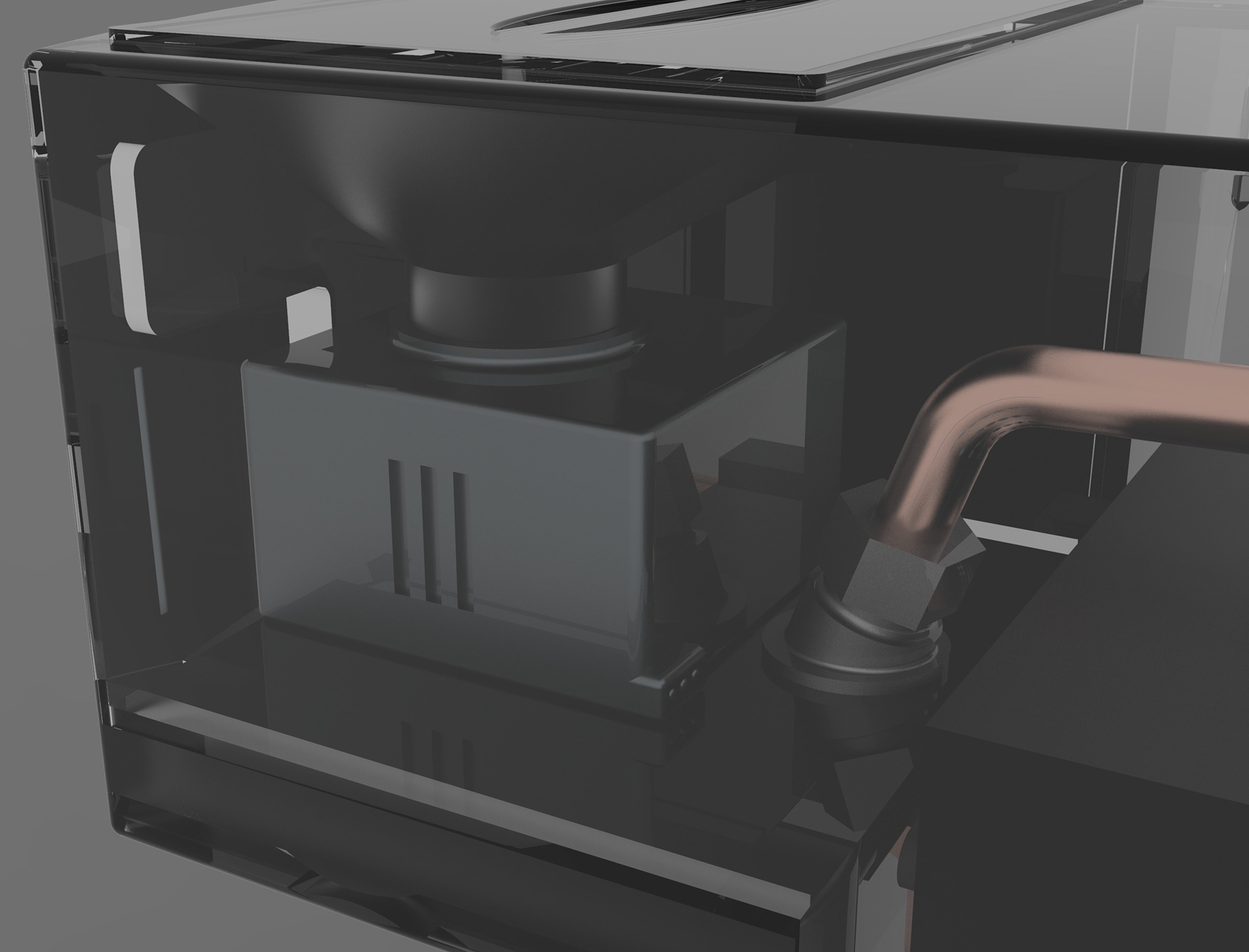

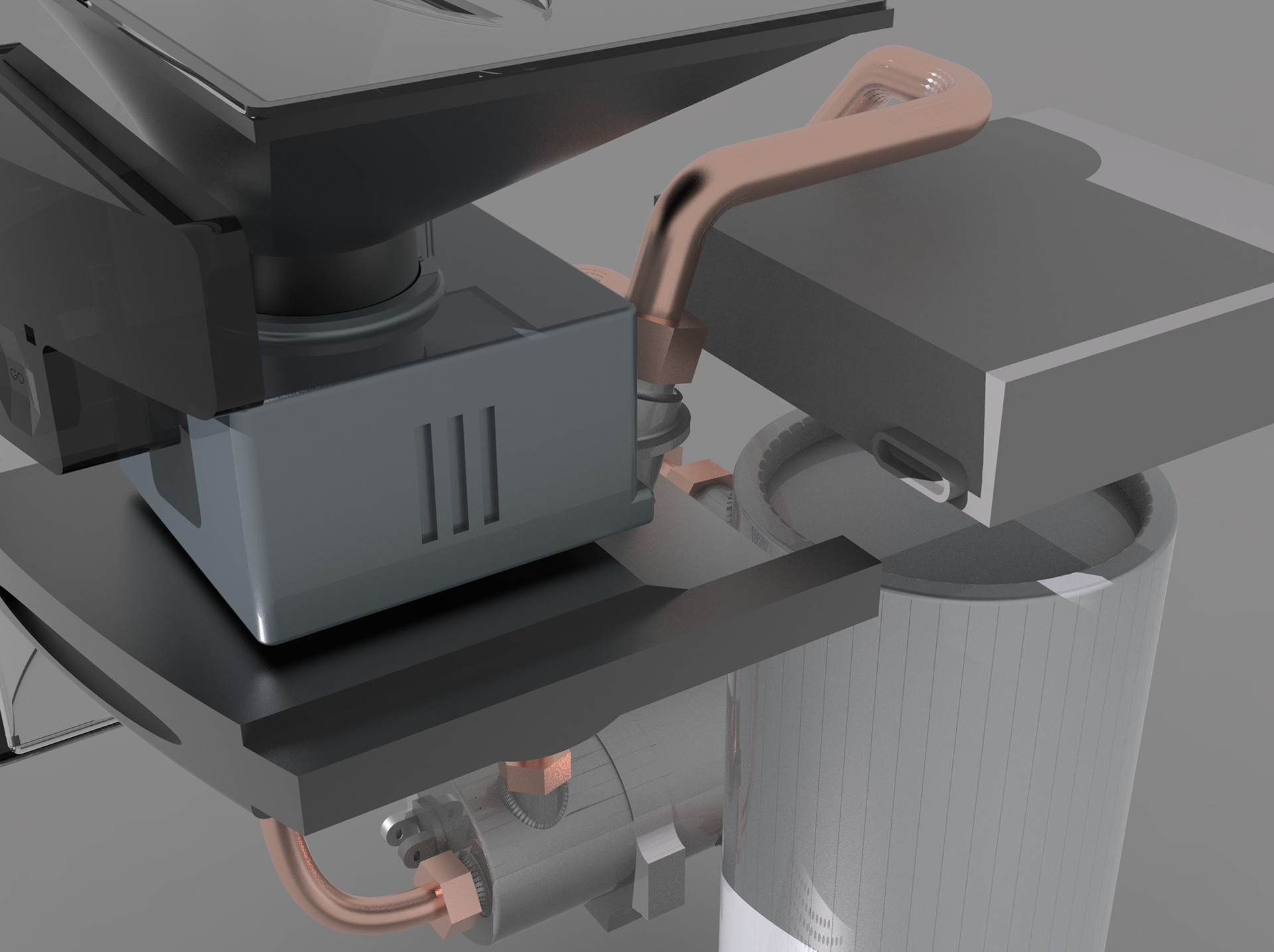

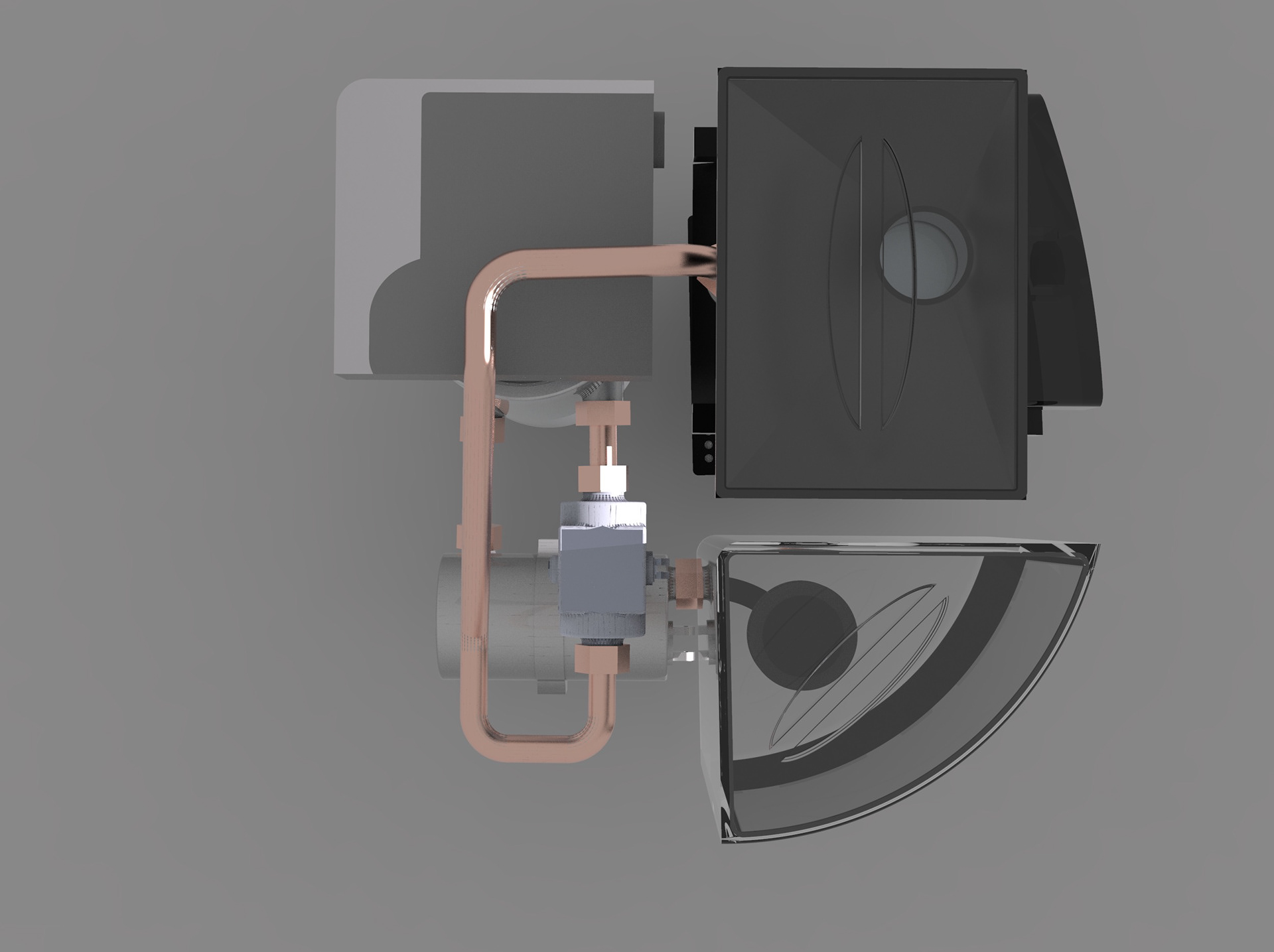

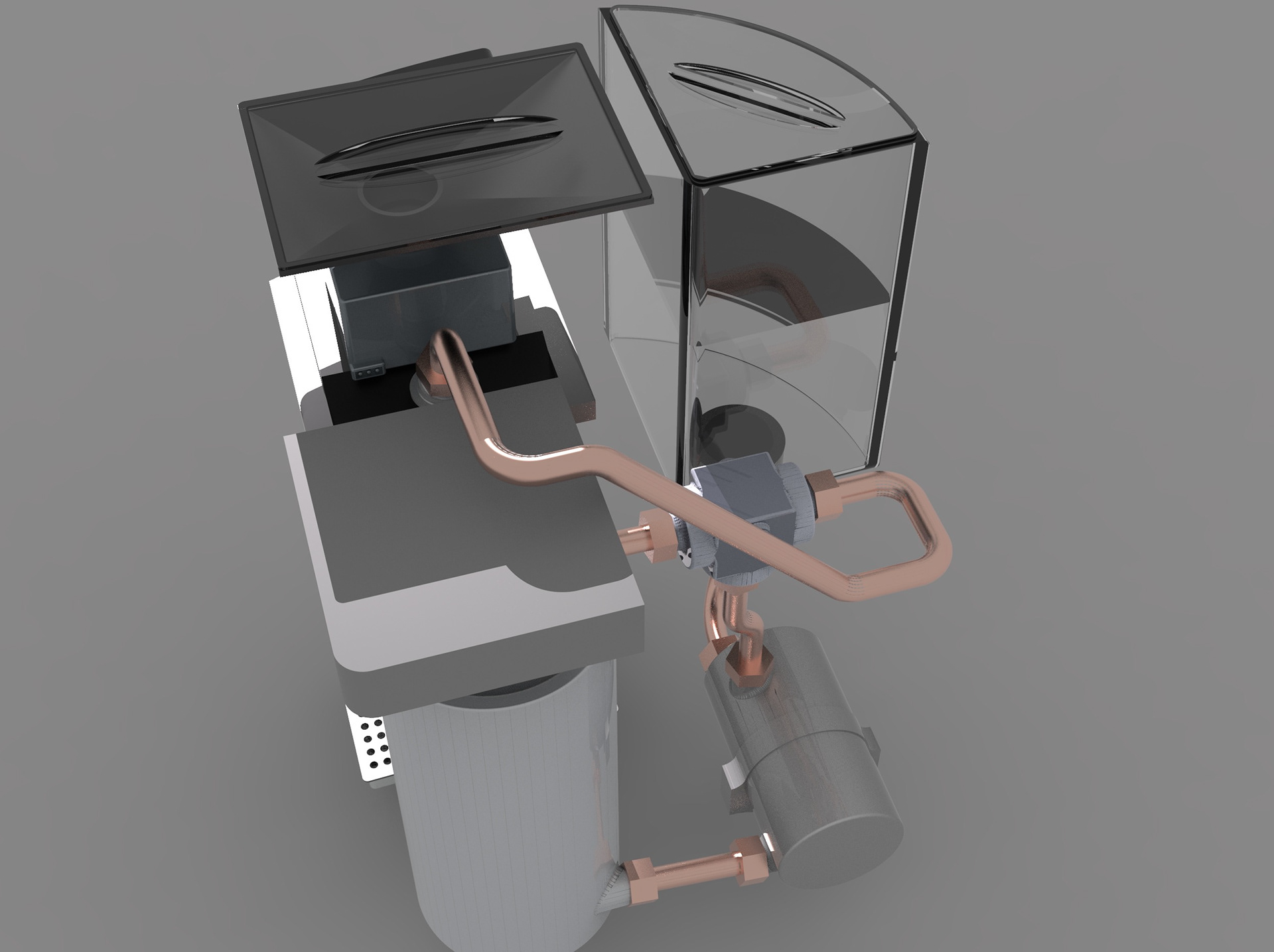

As the visual sketching had focused on form. It was also important to show how the machine would work technically due to an espresso machine naturally having a number of internal components. A lot of these components come already manufactured as well as some being of minimal cost to manufacture. The machines layout was also derived from this clearly show the development certain components such as the valve mechanism for the water tank and the water circuit from the boiler to the filter.

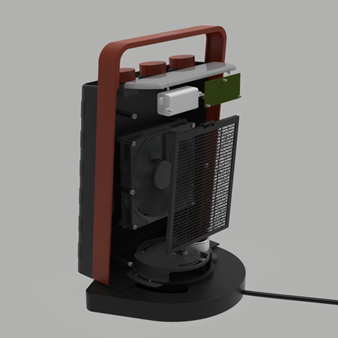

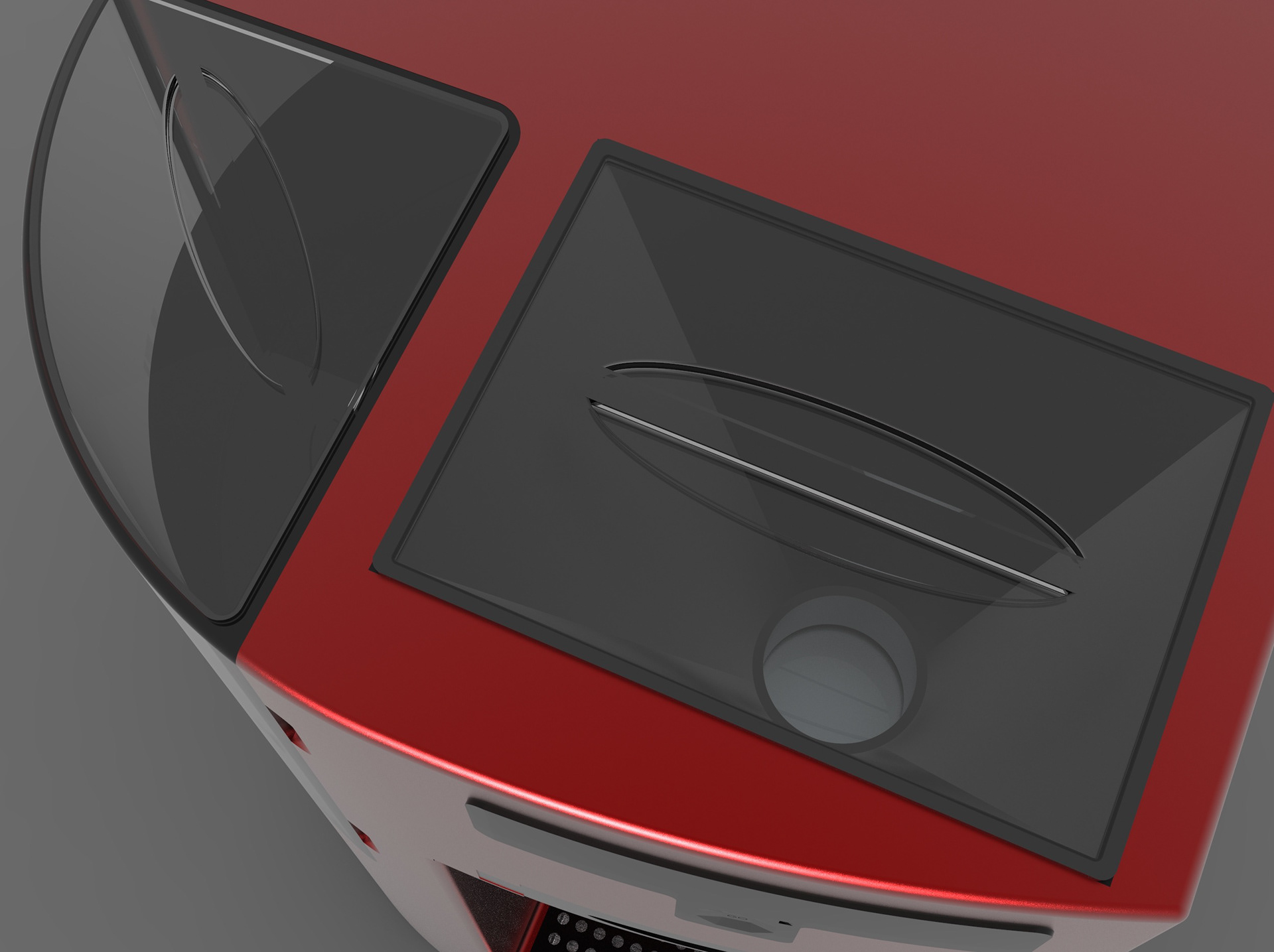

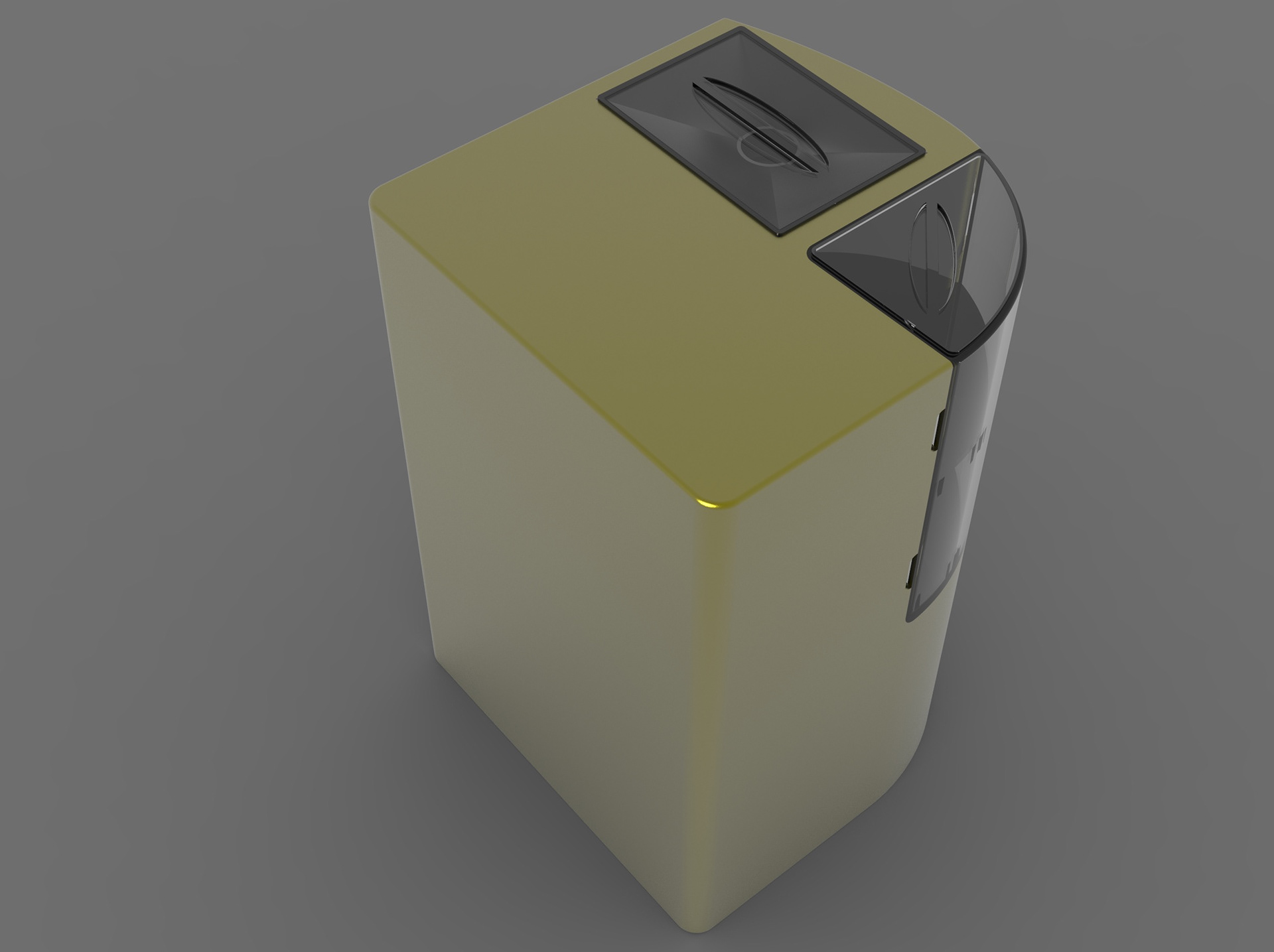

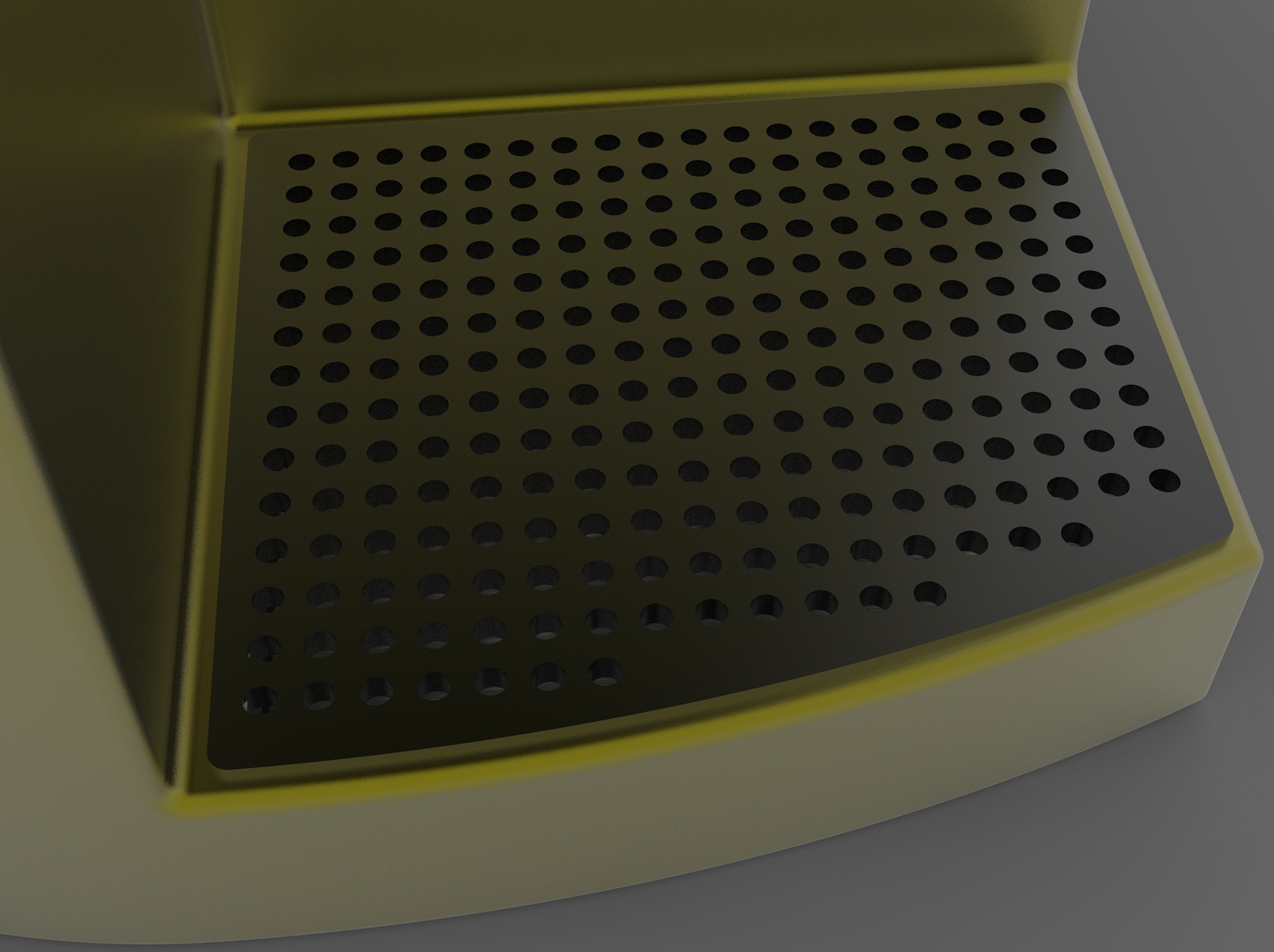

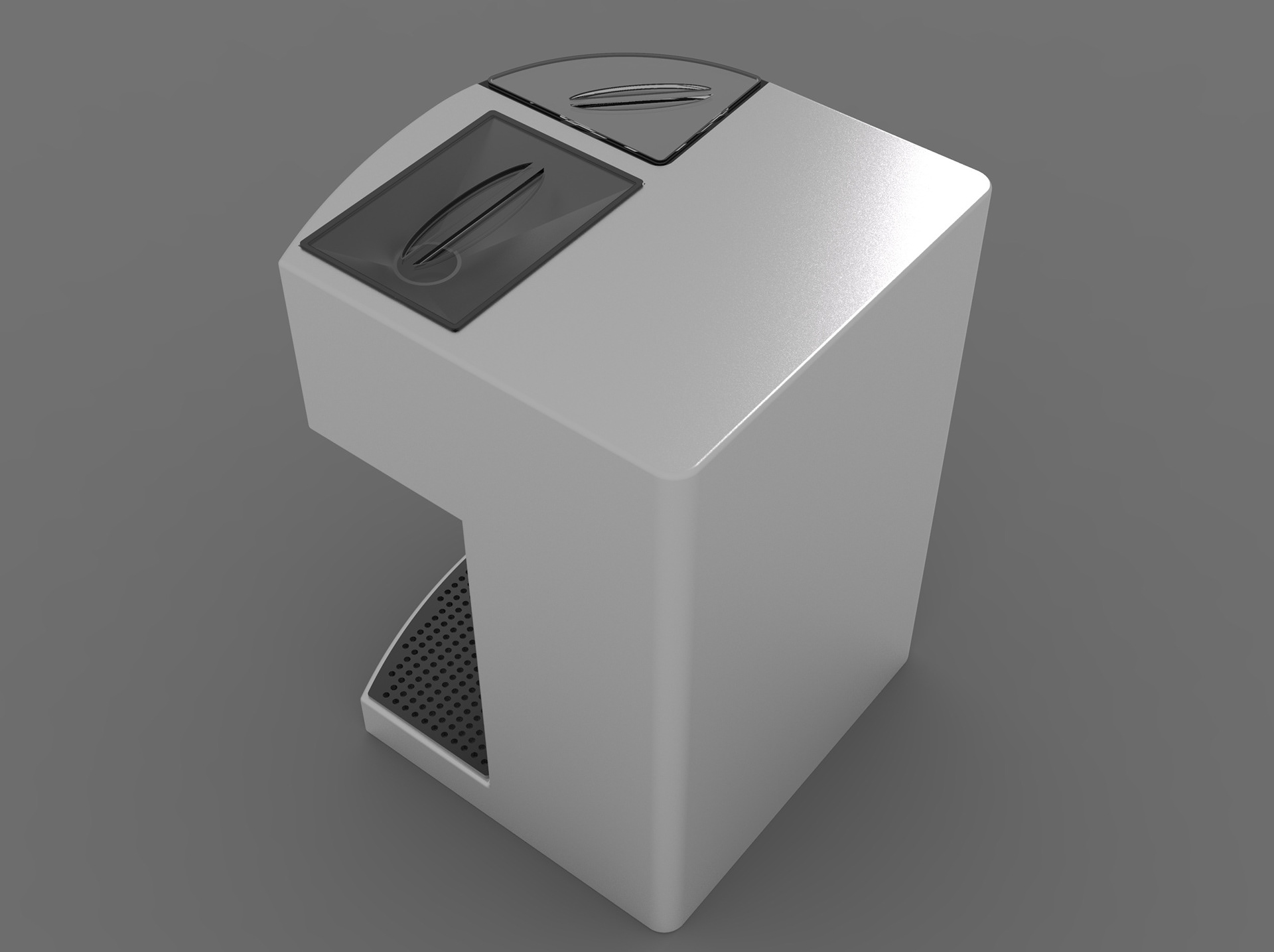

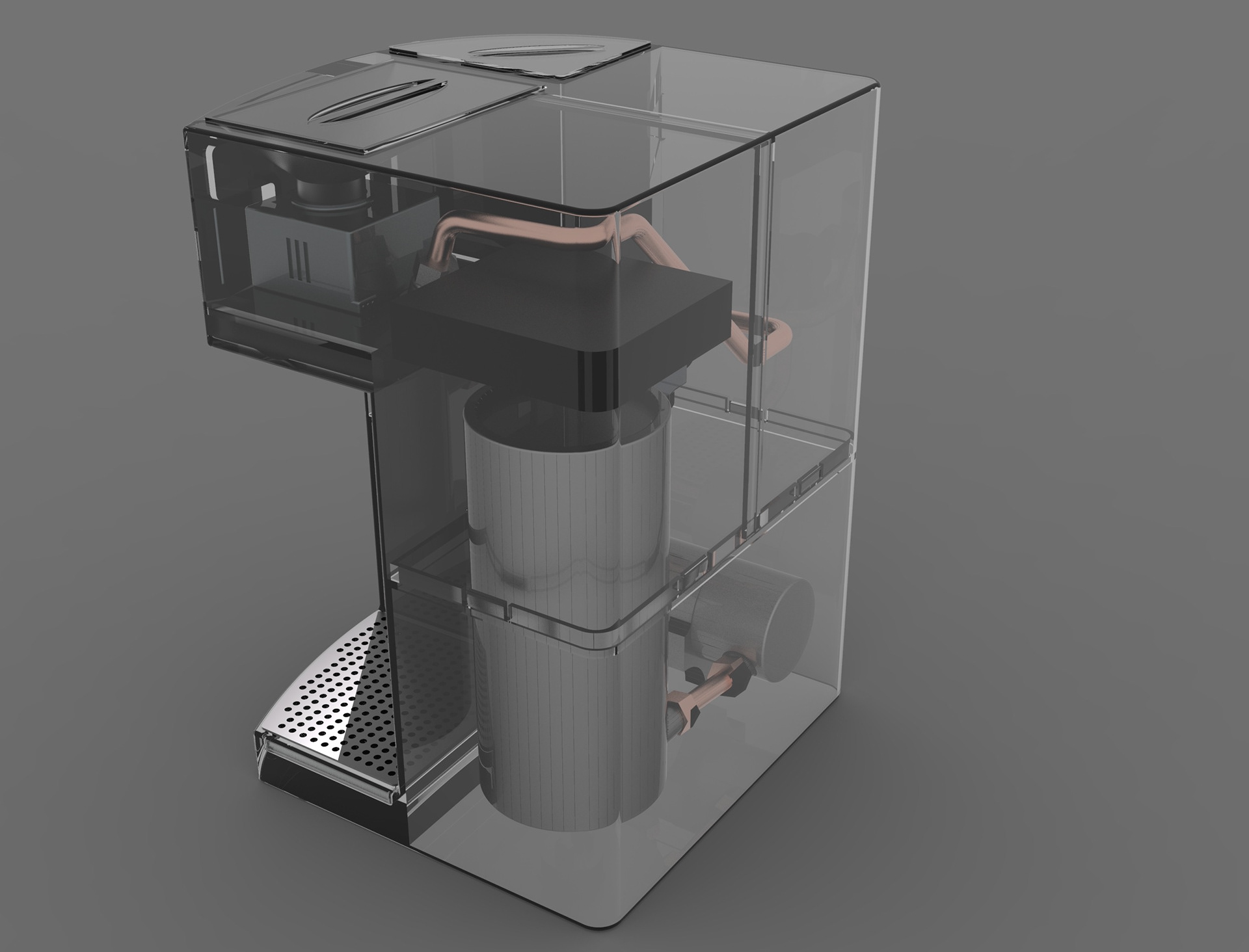

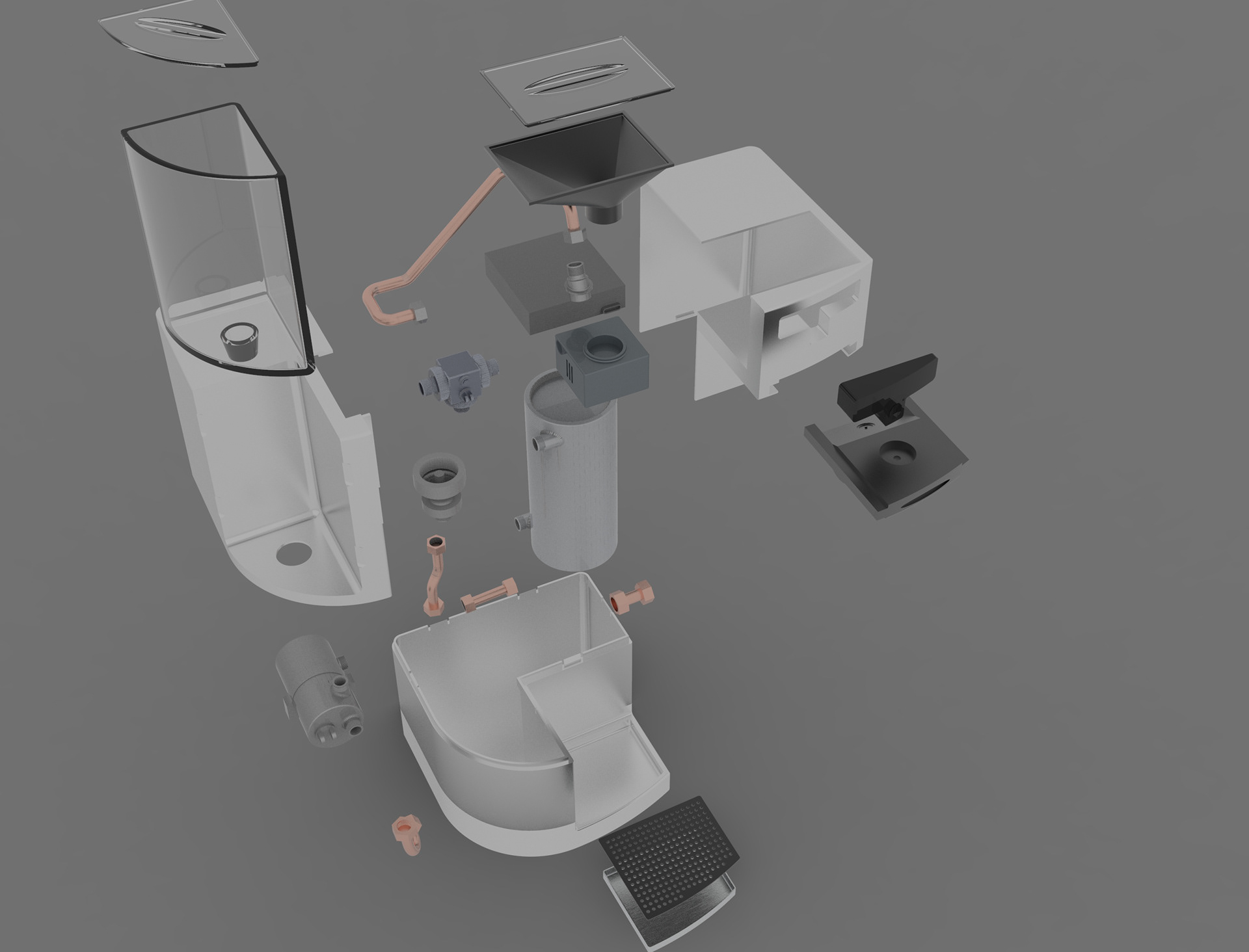

A CAD model was then made in solidworks with all the internal components and piping modelled. Then, using KeyShot, the model was rendered to show material finishes and small details.

To visually convey my design through CAD as set out in the brief. A series of glass renders were produced to show all of the internal components were situated as well as supplementing the 2D technical drawings.

An exploded view of the machine was also rendered to show all the of the seperate components in their entirety.

Key Summary of Skills Used in this Project:

Research of Current Trends, Market Research, Reverse Engineering, Sketching, Looks-Like prototyping, Solidworks Modelling, Rendering using KeyShot.