Lowe alpine - Sustainable Frame Bag

Lowe Alpine produces many world class carry systems per year. As a result, a lot of fabric wastage comes as the result of this and in unavoidable.

This is due to fabrics being bought in minimum order quantities set by the manufacturers.

Design an acessory that embraces this fabric wastage and uses existing stock. This in turn will reduce Lowe Alpine's environmental footprint and monetary wastage.

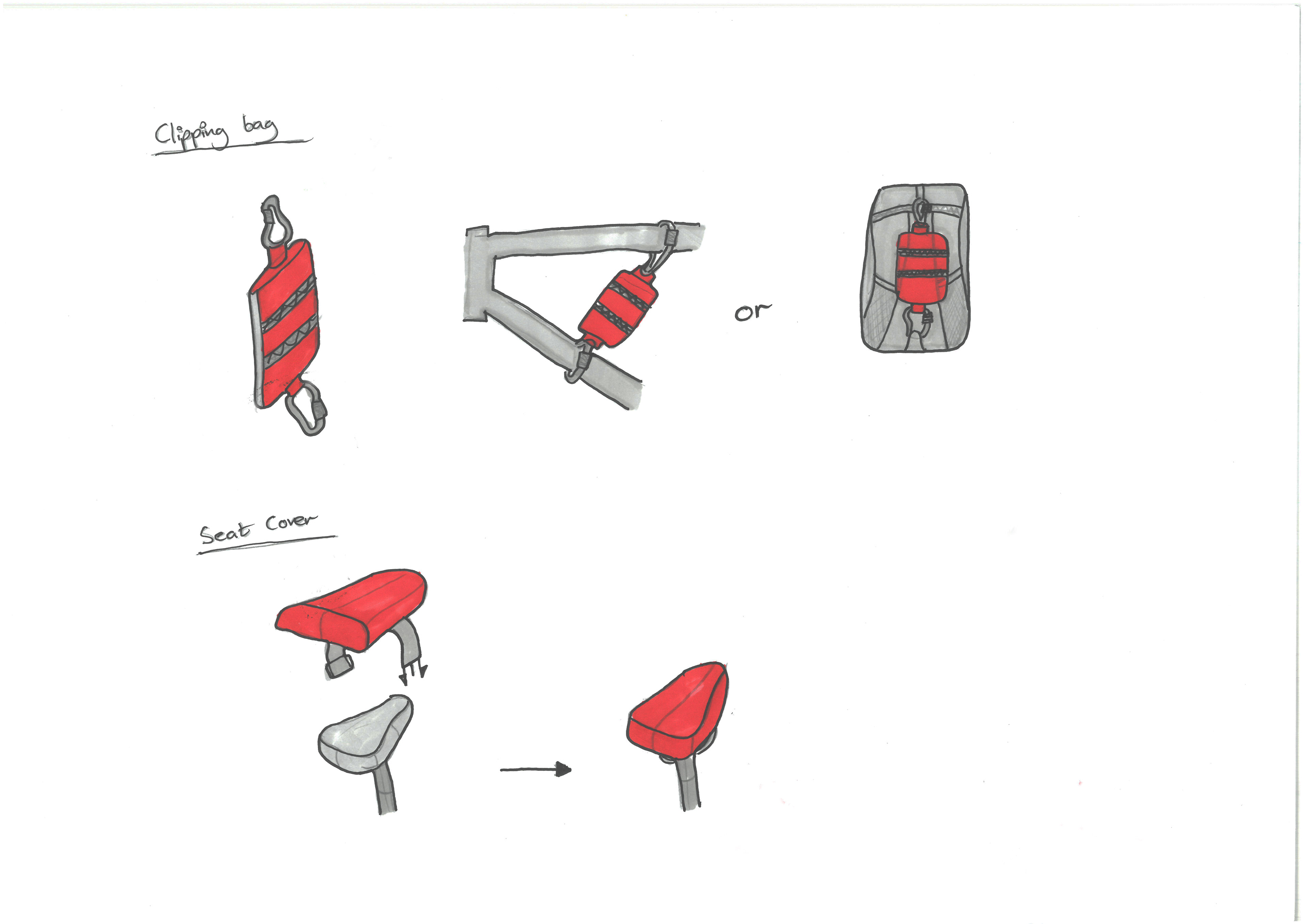

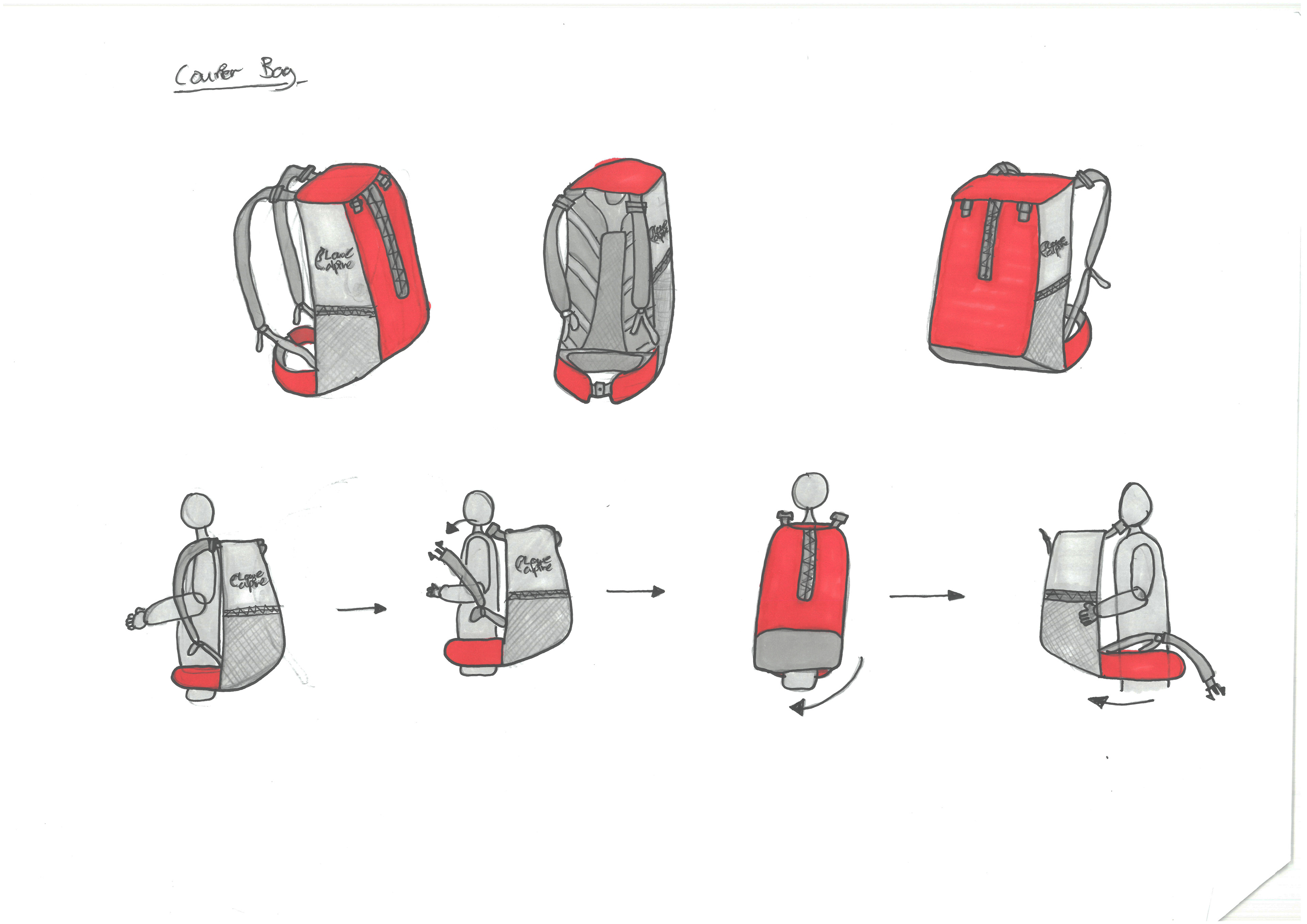

As a result of this waste fabric, the frame bag was ideated! the bag itself doubles as a normal over the shoulder single strapped bag, also being a bag that attaches/detaches easily from a bike frame.

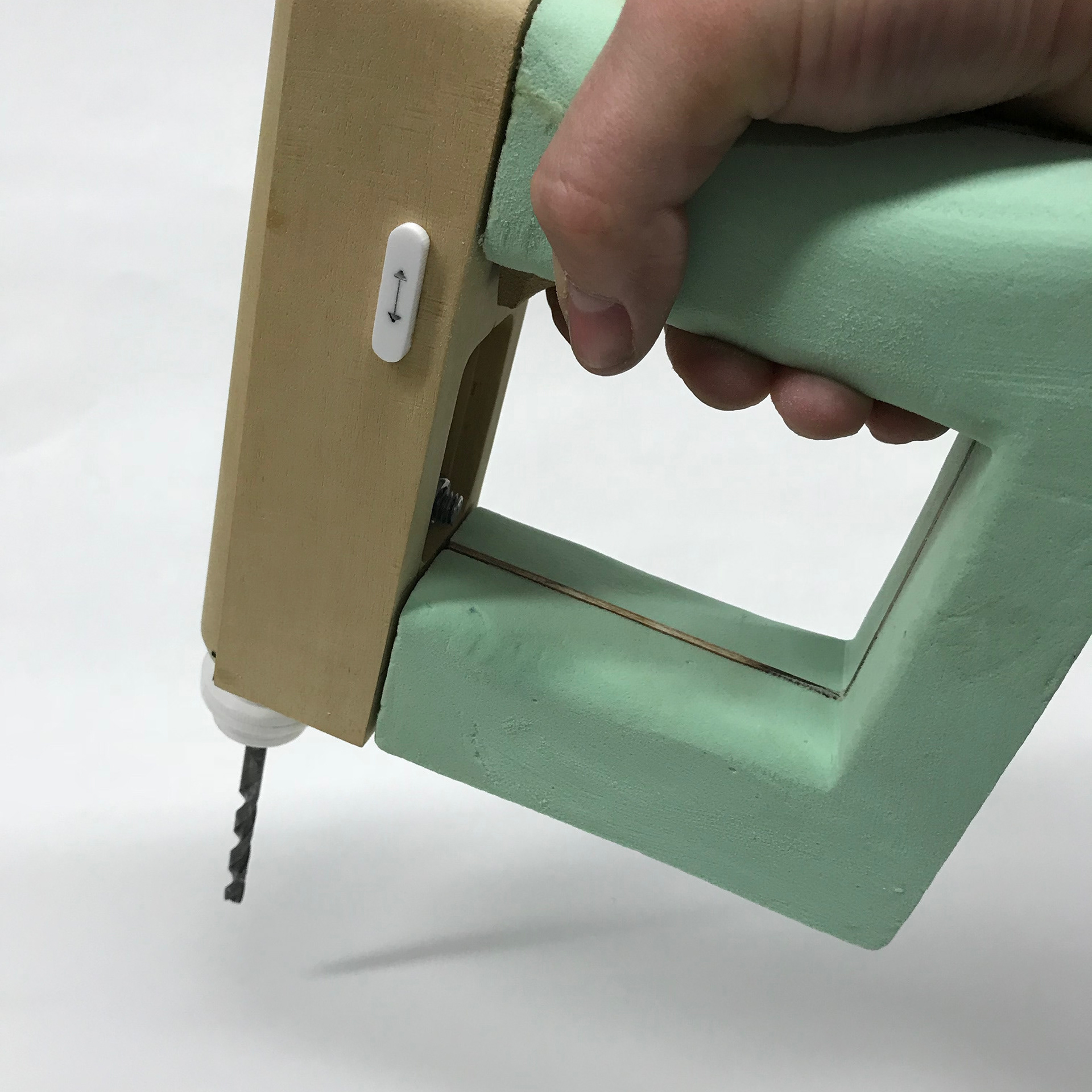

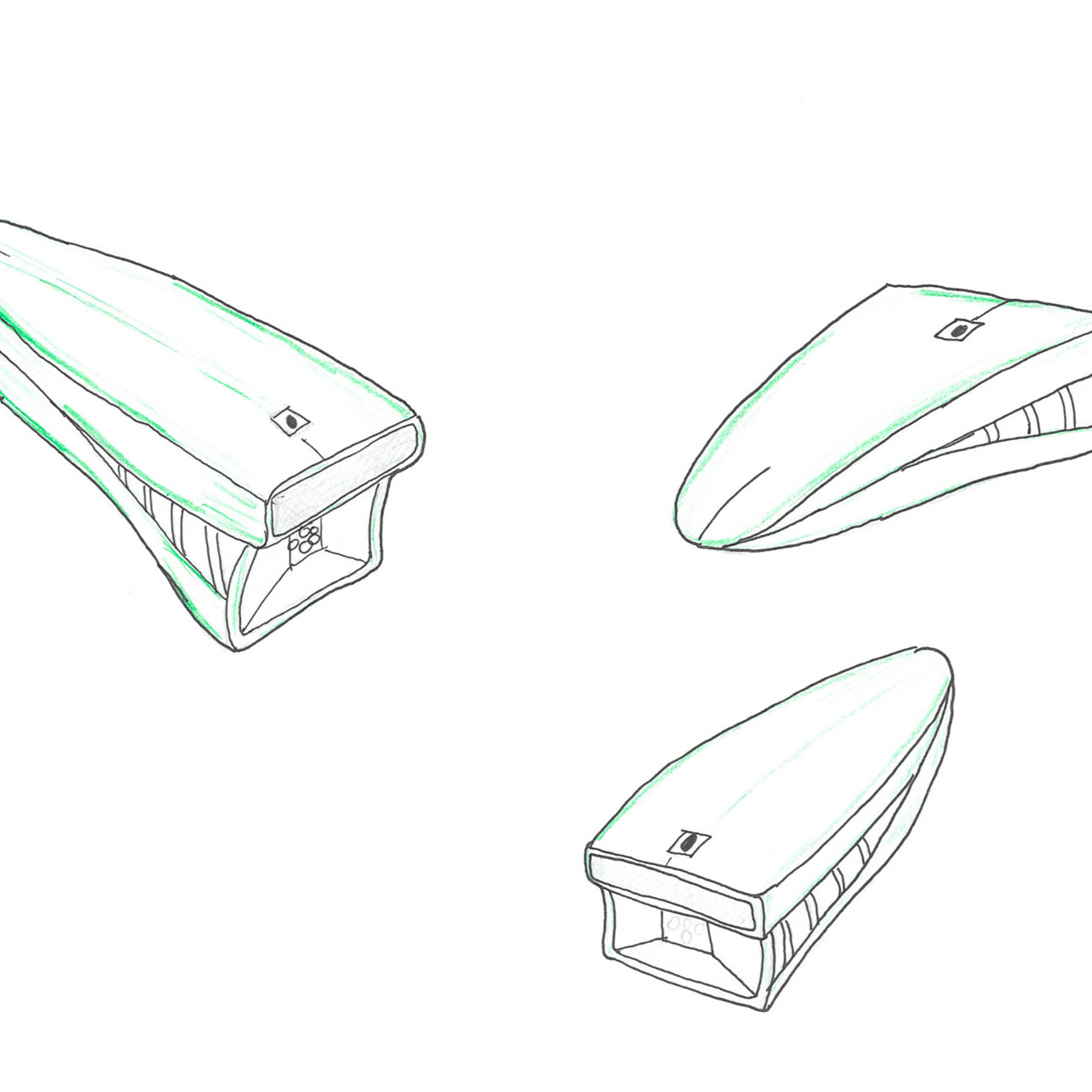

After devising three concepts, a final concept was chosen and the prototype concept of the final product was produced. Below are photos of the development process and the series of prototypes made to reach a final design.

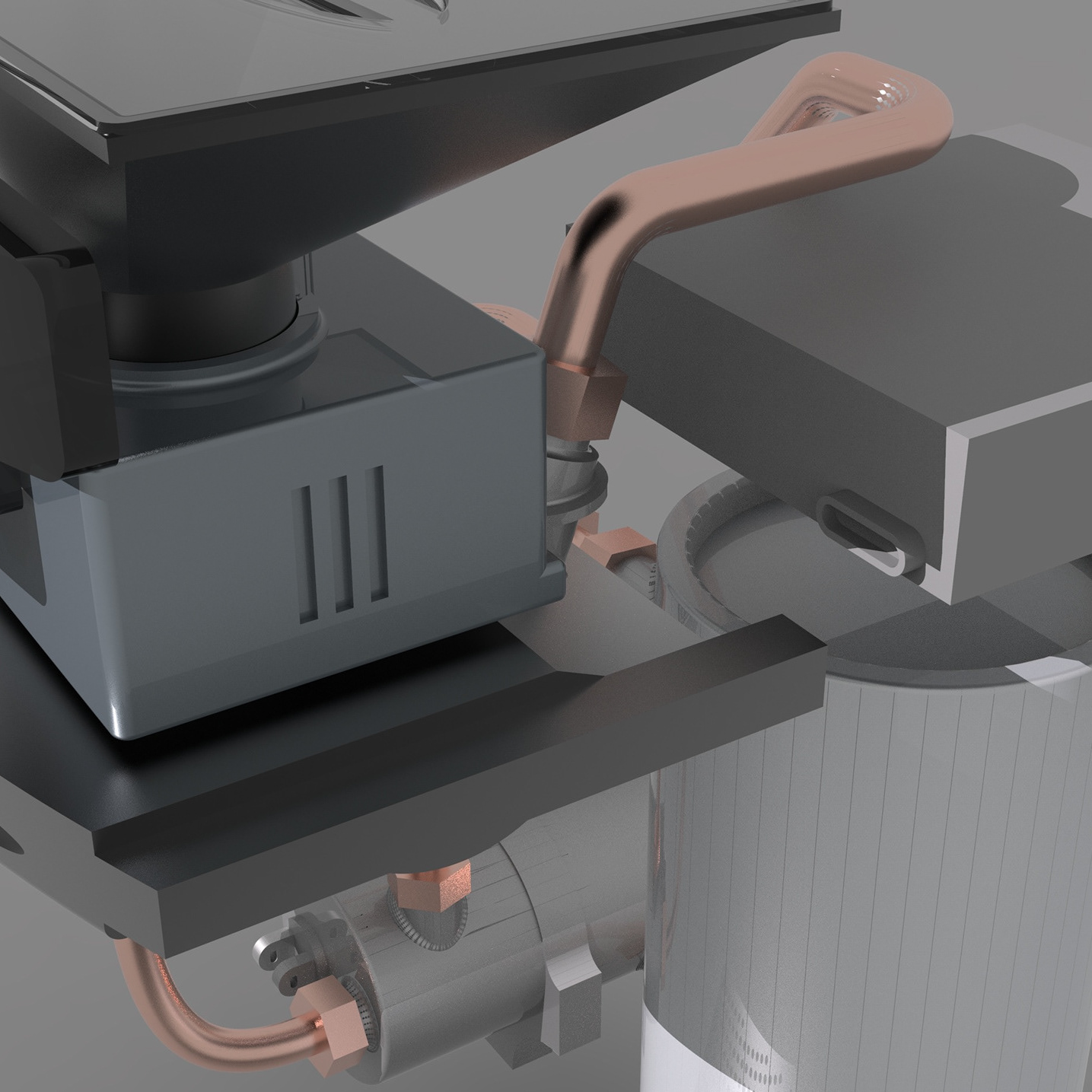

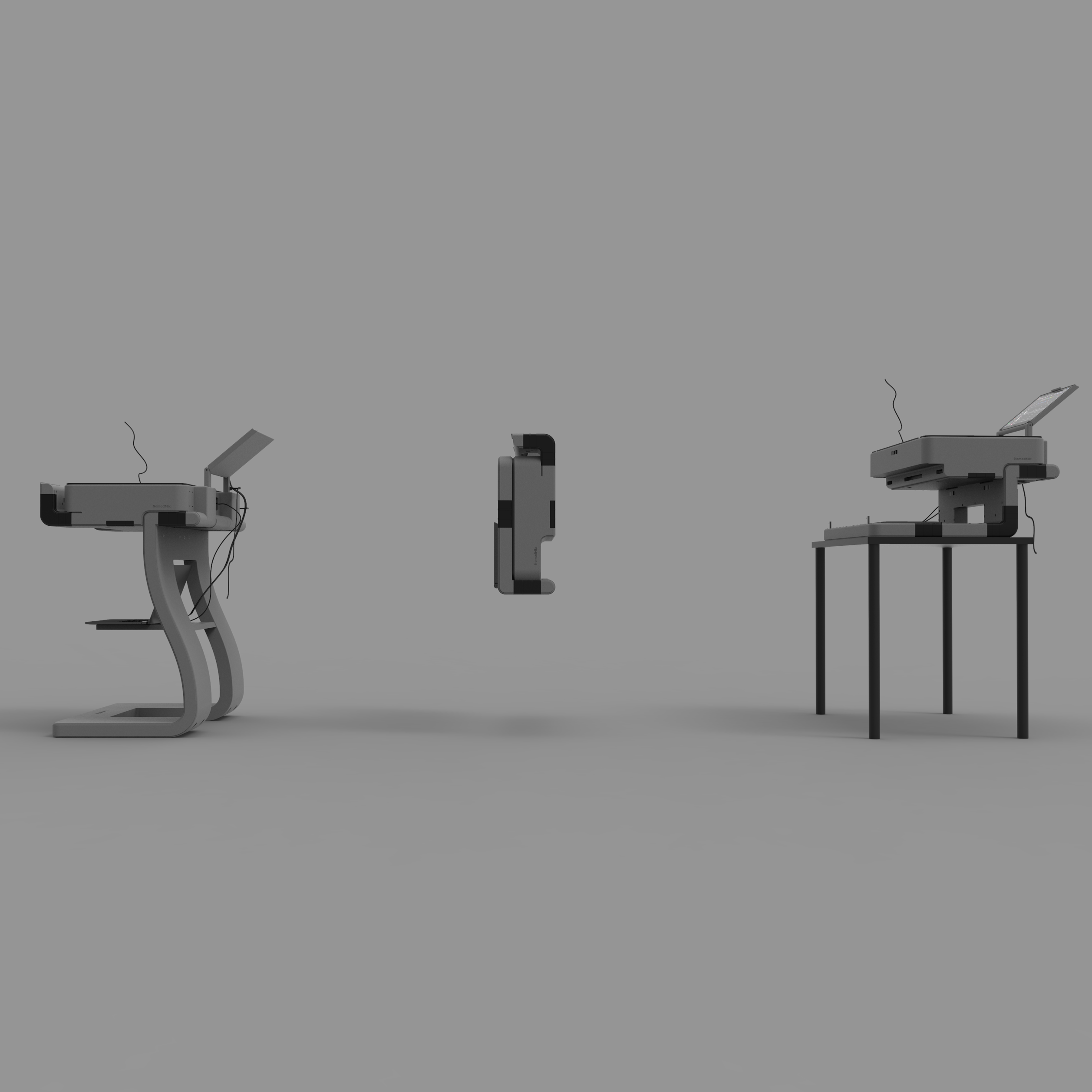

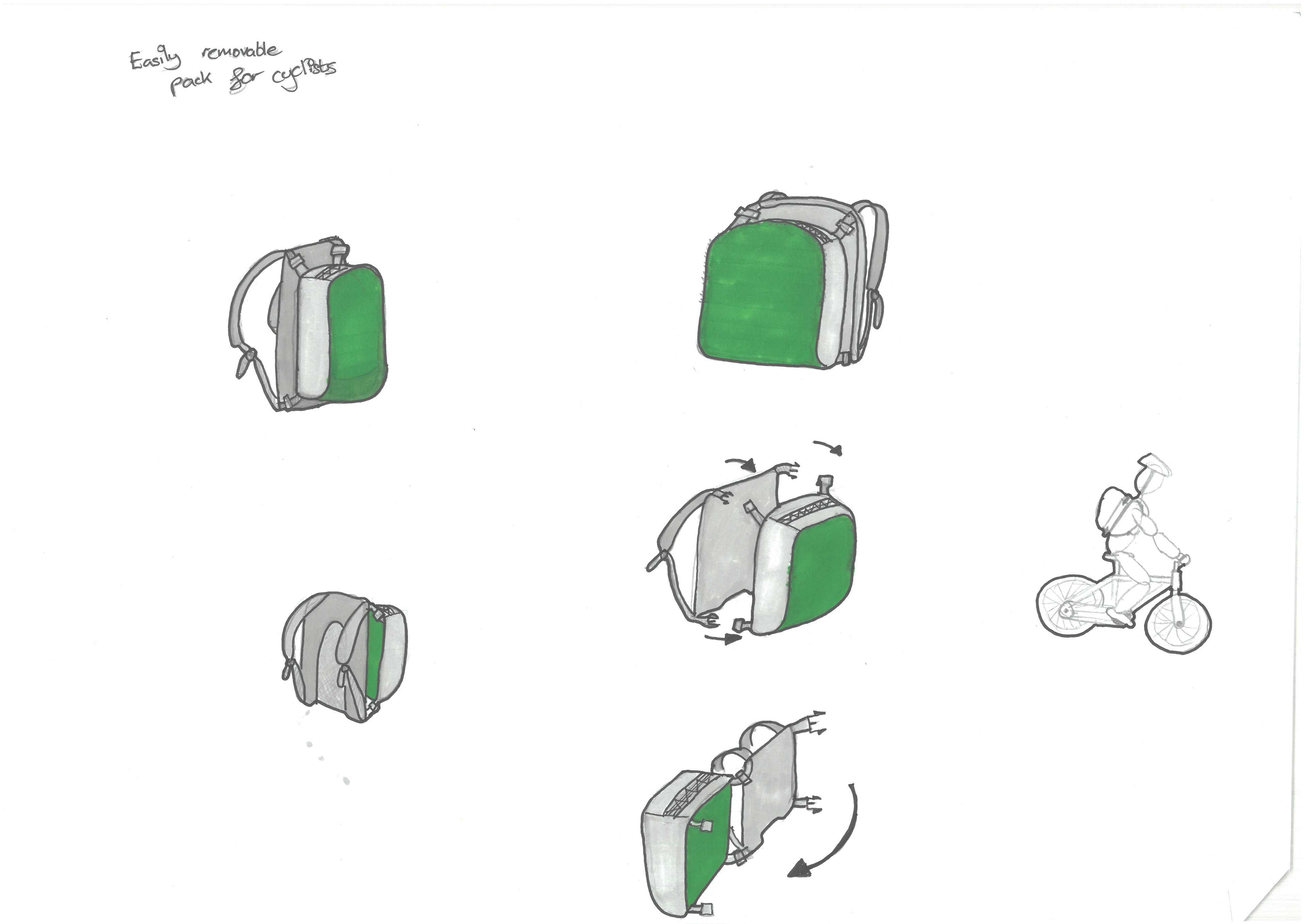

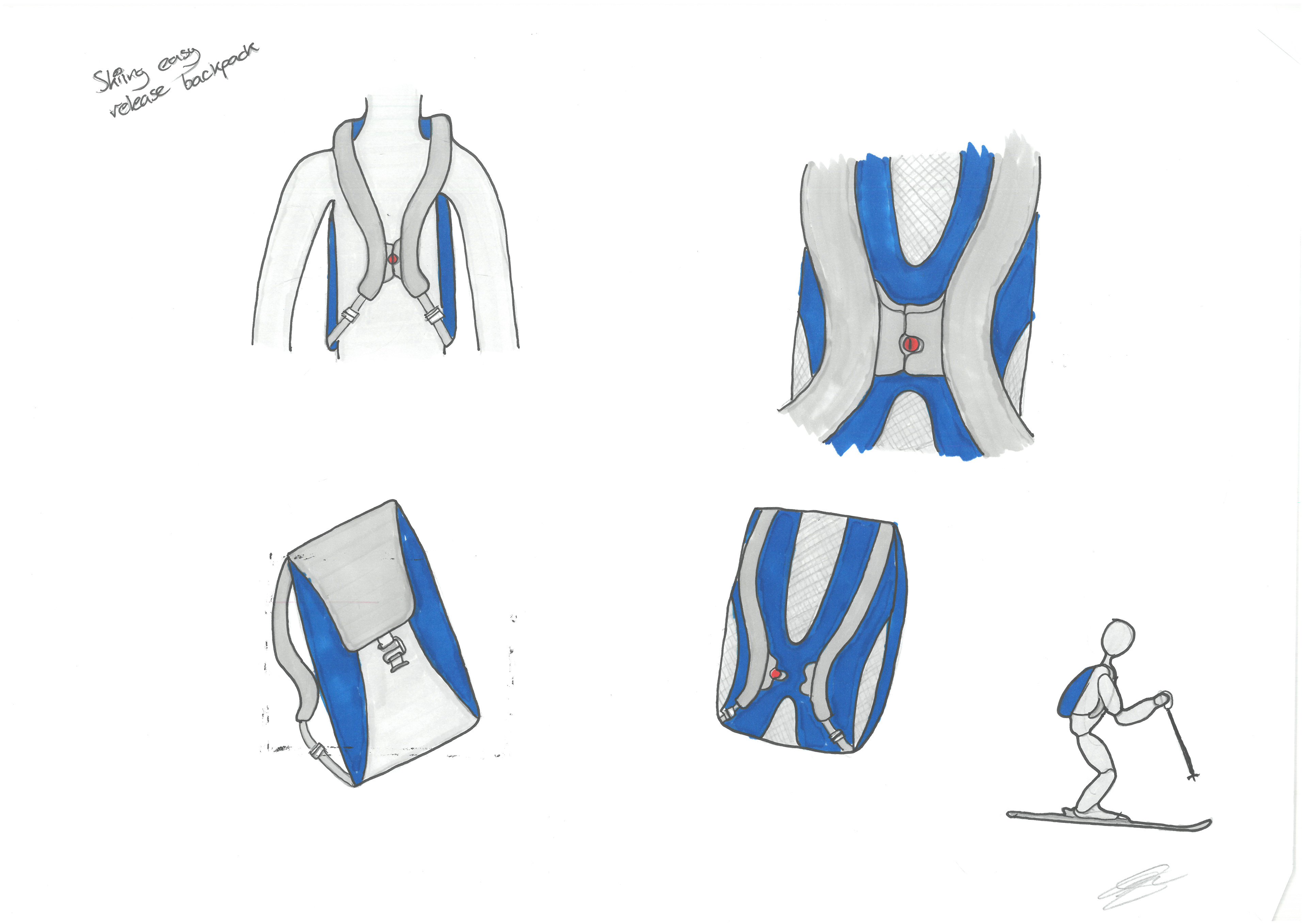

The key decisions made in the whole development process were the actual logistics of how a bag could attach firmly to a bike frame but be versatile as a shoulder bag. The considerations of size and shape had be at the forefront due to this being critical in terms of fitting day-to-items in for work as well as not restricting the users pedalling motion.

The ways of fixing the bag to the frame as well as making it easy to detach and attach were also another consideration with the final decision of using a clip fixing due to it's ruggidness.

The skills developed through the project were mainly that of fabric laying and stitching. As with other projects being model making using hard materials. The use of soft materials challenged the norm and really put myself out there in compared to my previous work.

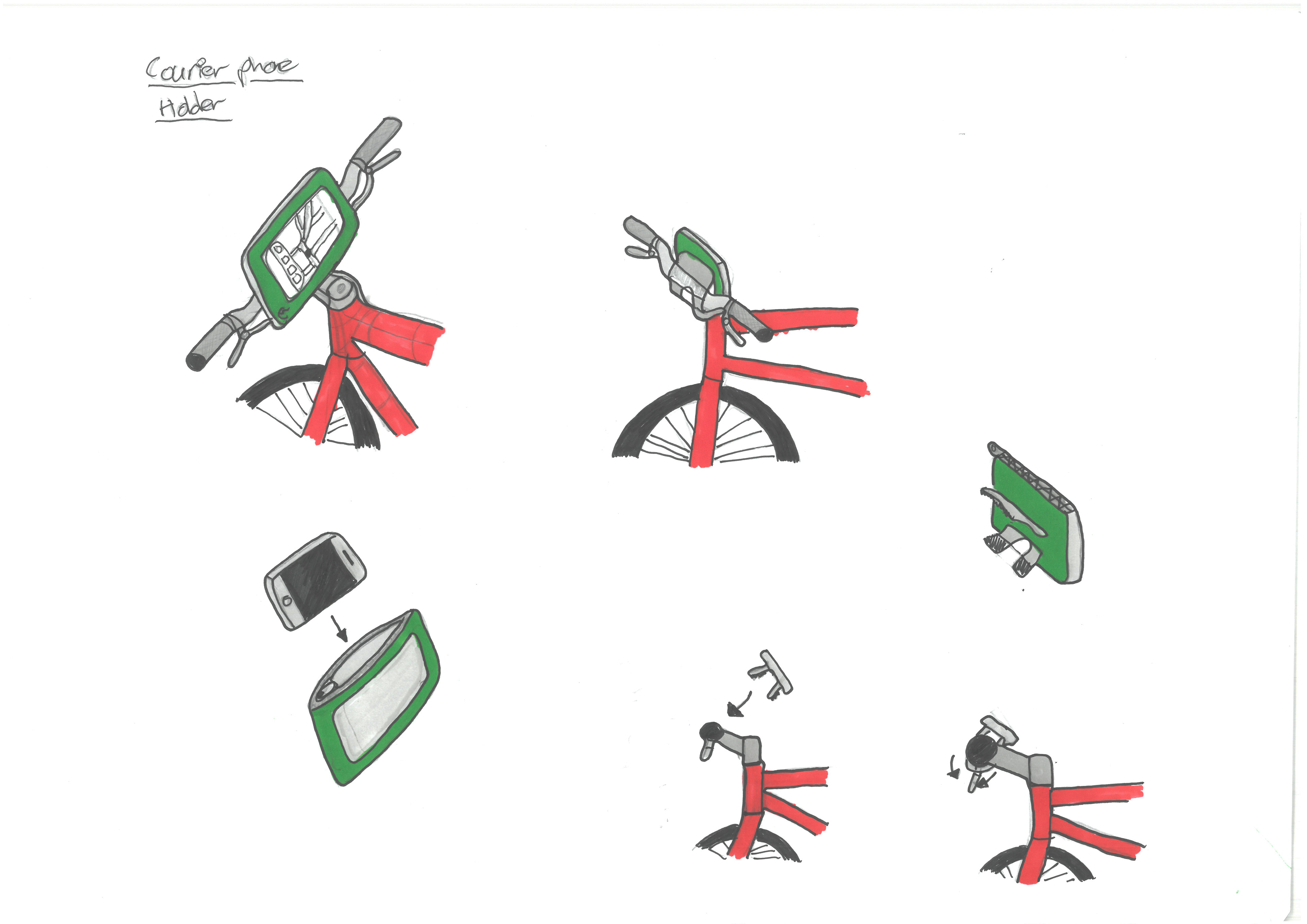

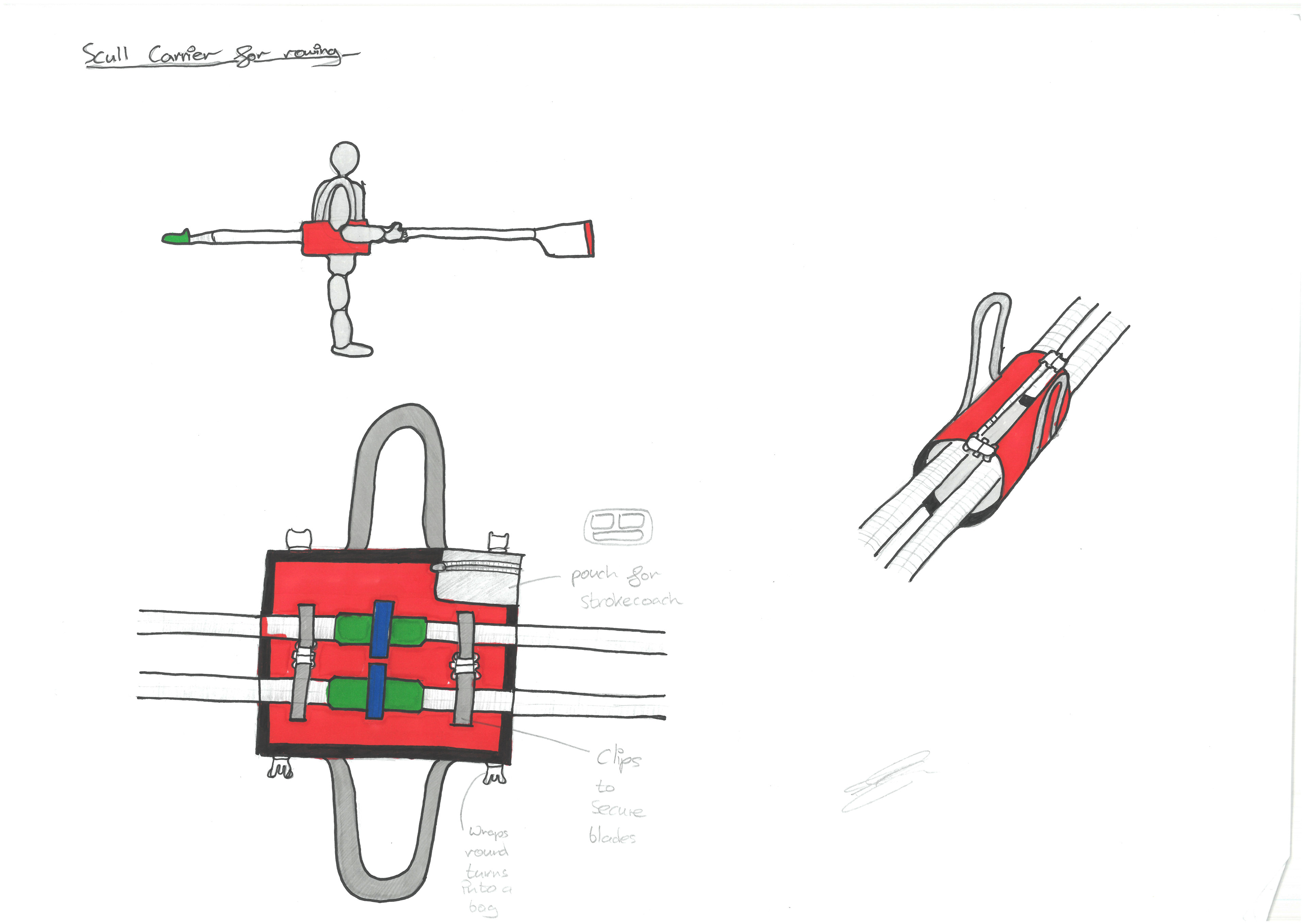

The sketching process during this project was of a very small and quick proportions as meetings with the design managers being very frequent. This required me to quickly conceptualise possible products as well as exploring different activities or sports that could represent Lowe Alpine as a brand to gain key user insight and probably market. The decision was made that cycling was to be the market focus due to it's widely expanding worldwide market.

To gain a key understanding of how fabric as a material works and how to pattern a bag properly with all relevant panels. A card bag was made by tracing each individual panel and cutting out the traced panel onto newspaper. The panels were then joined together by masking tape. This process turned out to be invaluable as it gave me insight to what was required in terms of manufacturing a bag or carry system and dictated size and form in terms of what my design could carry.

The prototyping process was similar to the sketching process in terms of the quick turnaround required. The models started off as simple cardboard cutouts to determine size and form as well as the different types of fixing methods whether it be using open ended hooks or velcro. The third iteration used an old Lowe Alpine coat in which the pockets where reused to act as pockets for the frame bag.

The overall design considerations were also important in terms of the user wearing the bag with it being comfortable while wearing it and allowing freedom of movement. The straps were also stitched to fit the colour of the main body and the main strap and internal seams being overlocked for structural rigidity. The Lowe Alpine logo was screen printed onto the bag using a industrial screen printing machine.

A counterpart feature of this project was that a small advert for my bag had to be created as to demonstrate it's context, purpose and features. This advert was created in Adobe Premiere and provided a clear concept to the client.

Summary of Key Skills Used in This Project:

Working Collabratively with Design Managers, Analysis of existing market and company products, Ideation of designs that reflect company ethos and design language through sketching, Prototyping and model making, Design for low environmental impact and waste reduction, Video Editing/Content Creation to display functionality.