Ergonomically-FOCUSed Cordldess Drill

The last project of first year was that of a Human Centred Design task. This involved designing a pre chosen existing product (cordless drill) with the aim to ergonomically enhance their functionality as well as the products form. The design must include fundemental features of the product such as speed control and safety features.

Skills used in the project

Task Analysis of chosen product, Existing Product Analysis, Reverse Engineering/Product Autopsy, Sketching, Modelling with Green/Prototyping Foam, Weighting models and using anthroprometric data to dictate form.

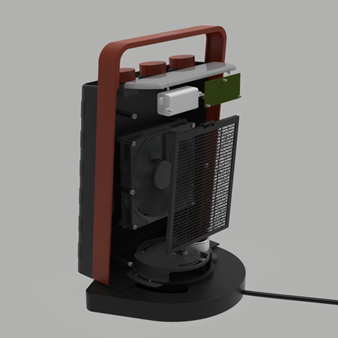

Functional Analysis was the first step in tackling the brief. This was used to understand how the drill worked as well as the reasoning for the locations for certain components such as the battery acting as a counterweight to offset the weight of the motor located above the users hand. This process was also used to gain insight on what functions could be better and how these functions could be ideated and redesigned.

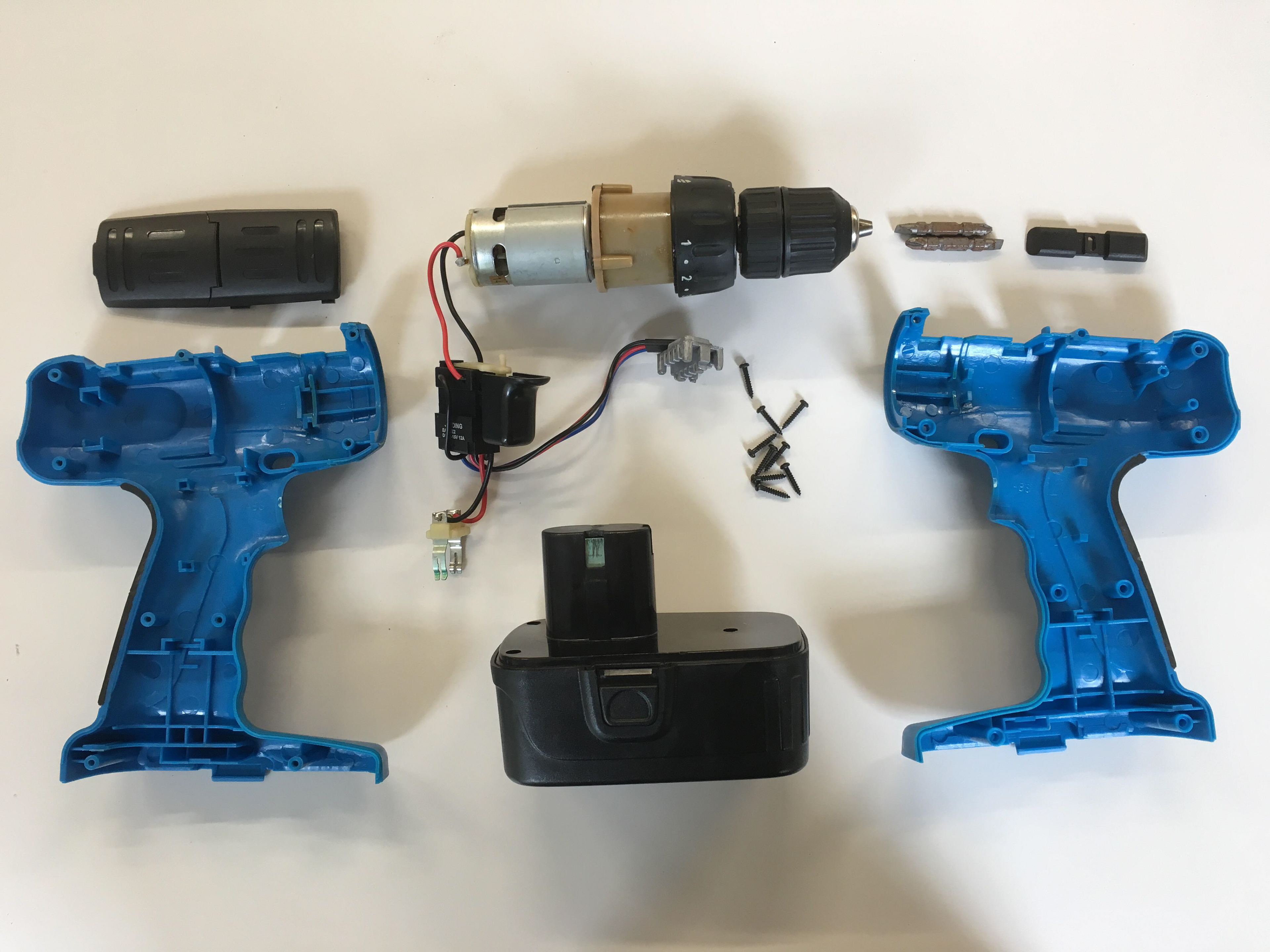

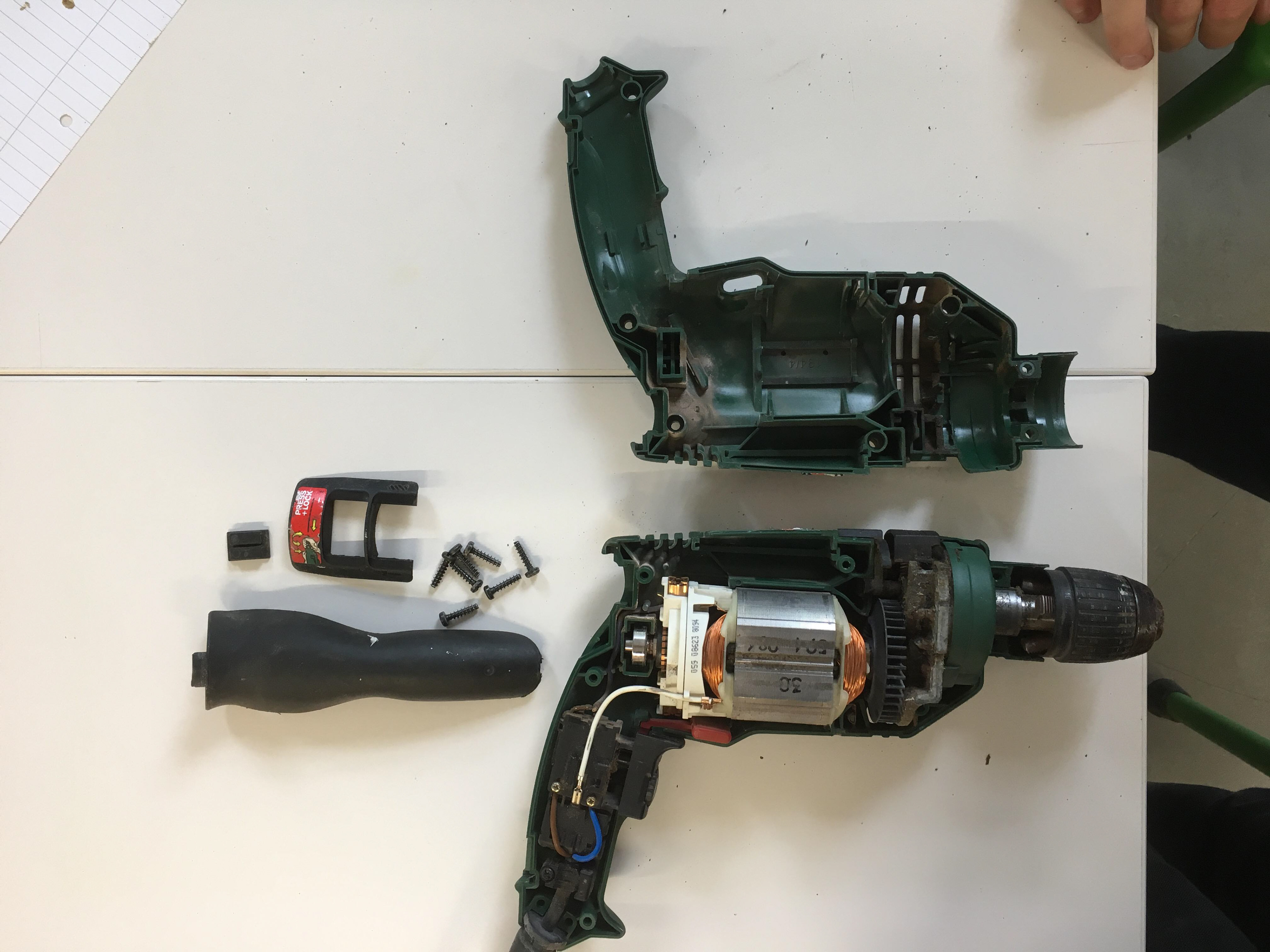

Reverse engineering was the next step in a bid to gain knowledge of the different components within a drill. As the prototype models had to be weighted to simulate the feel of a real drill. The weights of these drills were recorded for future reference.

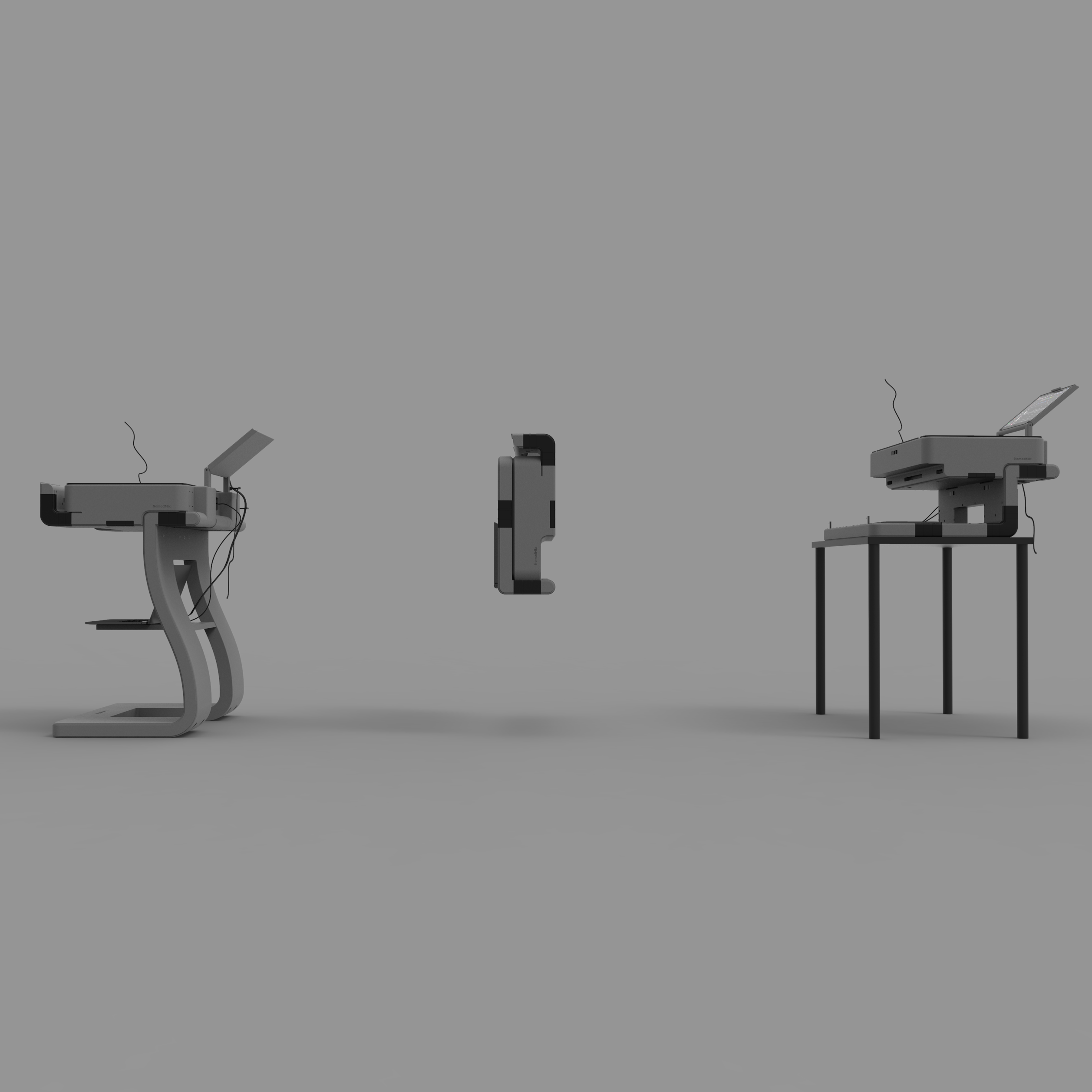

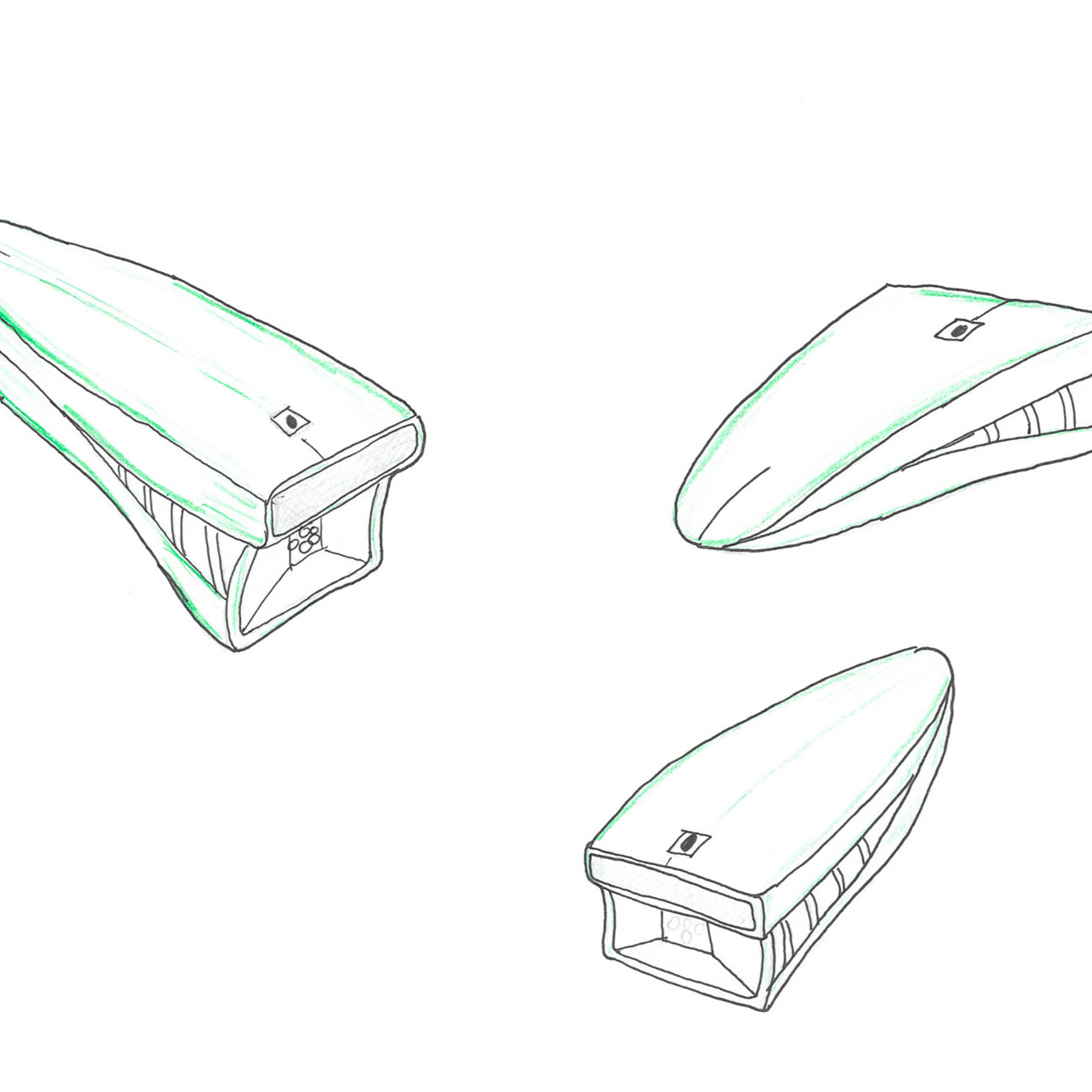

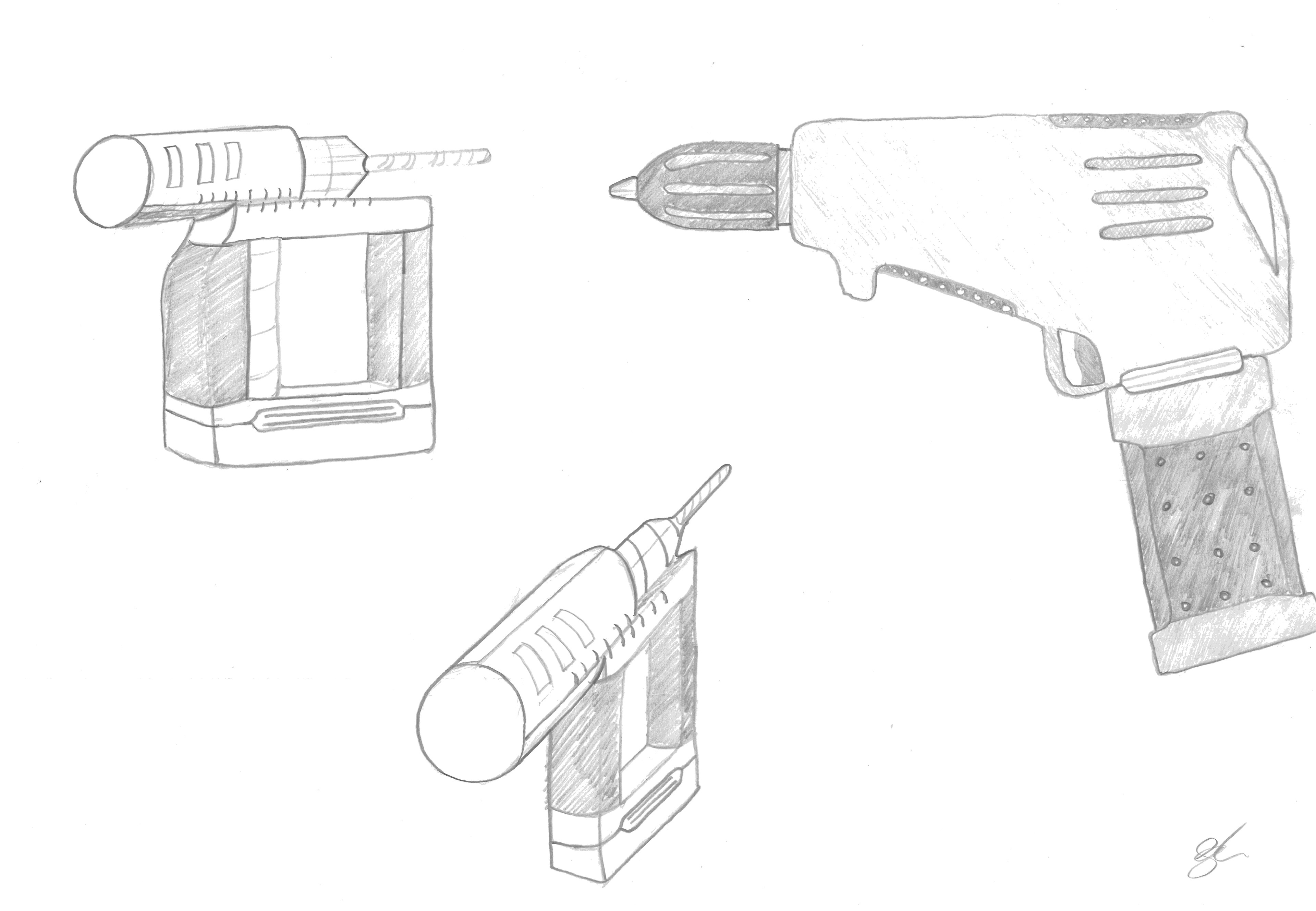

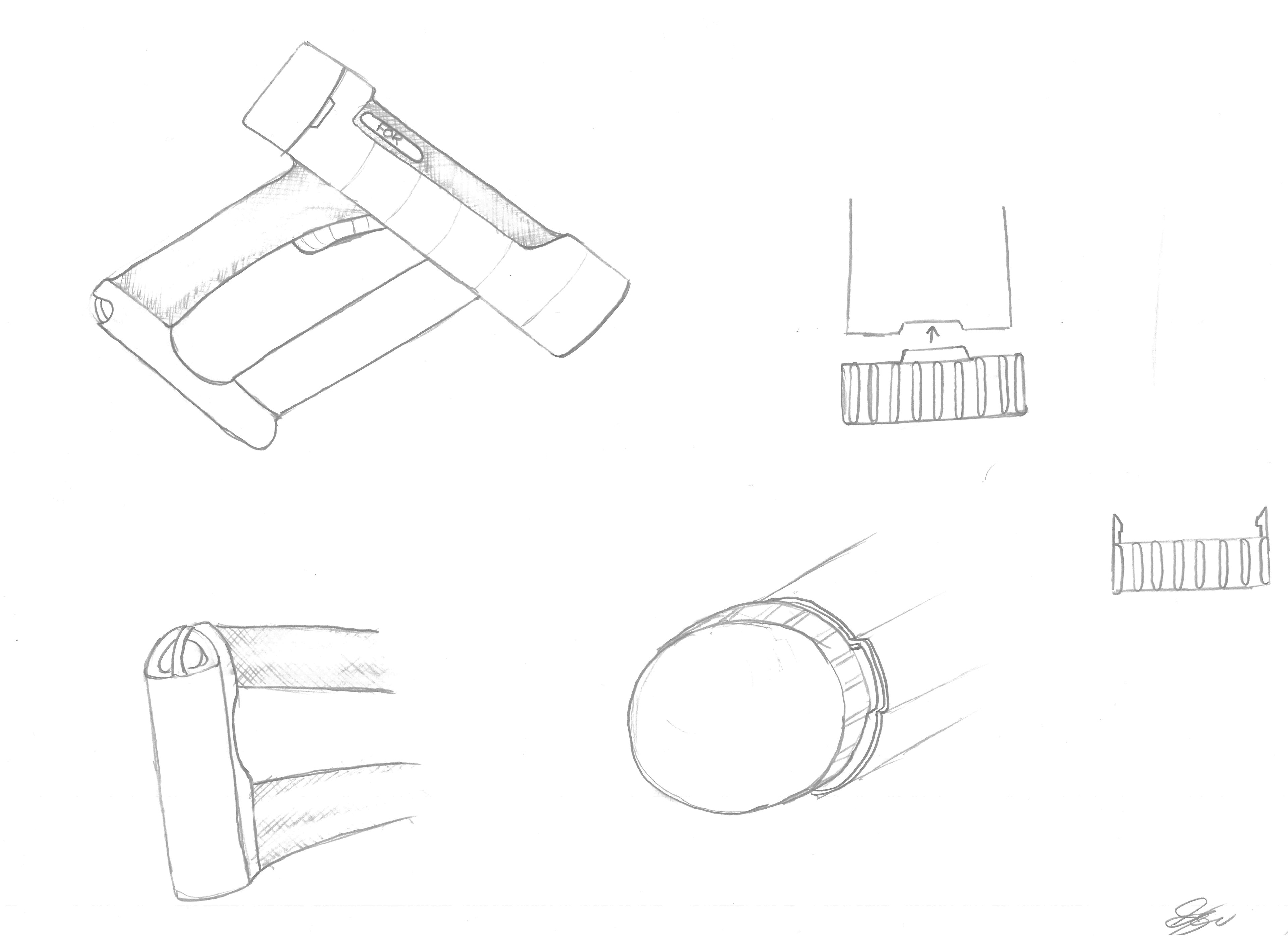

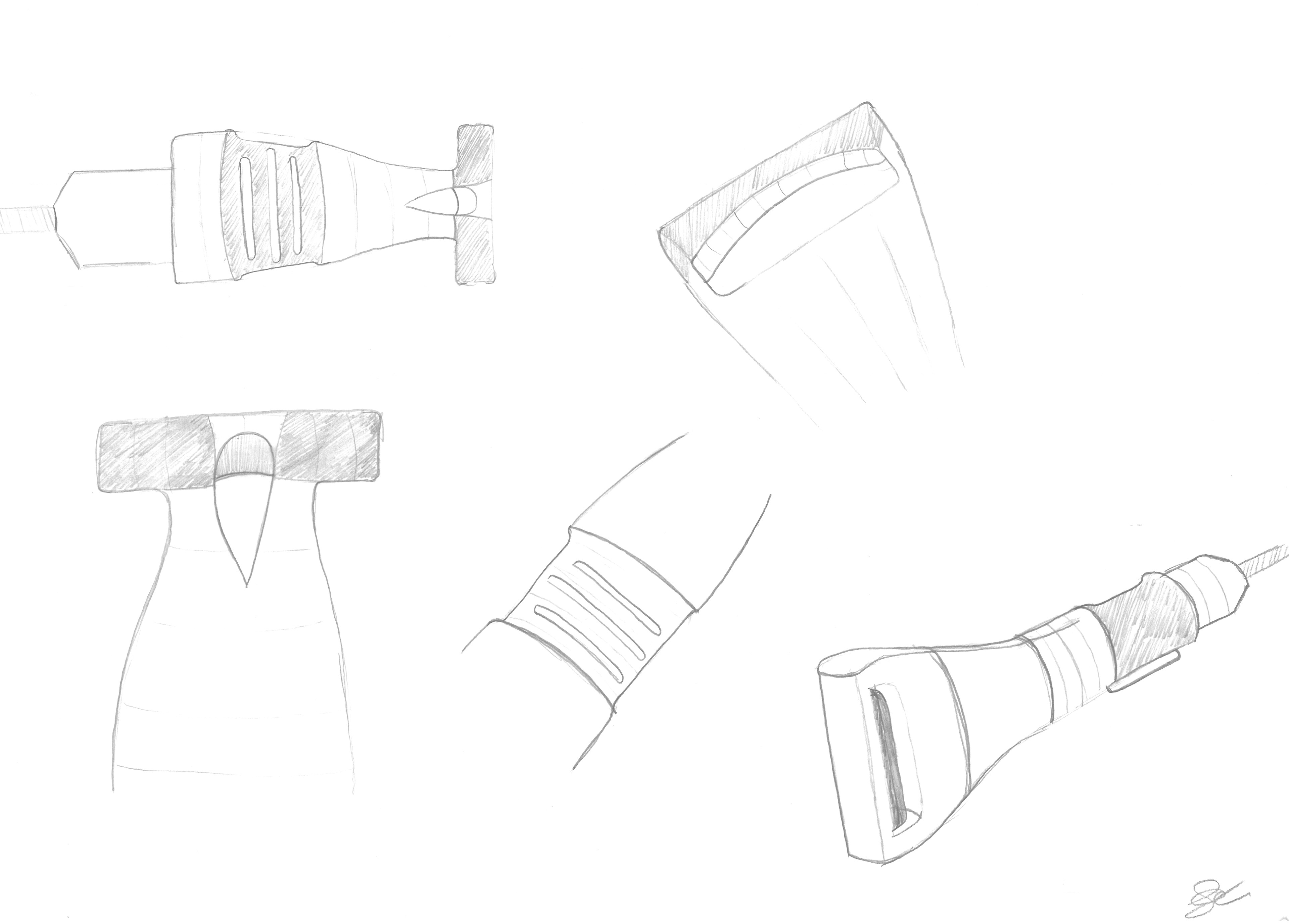

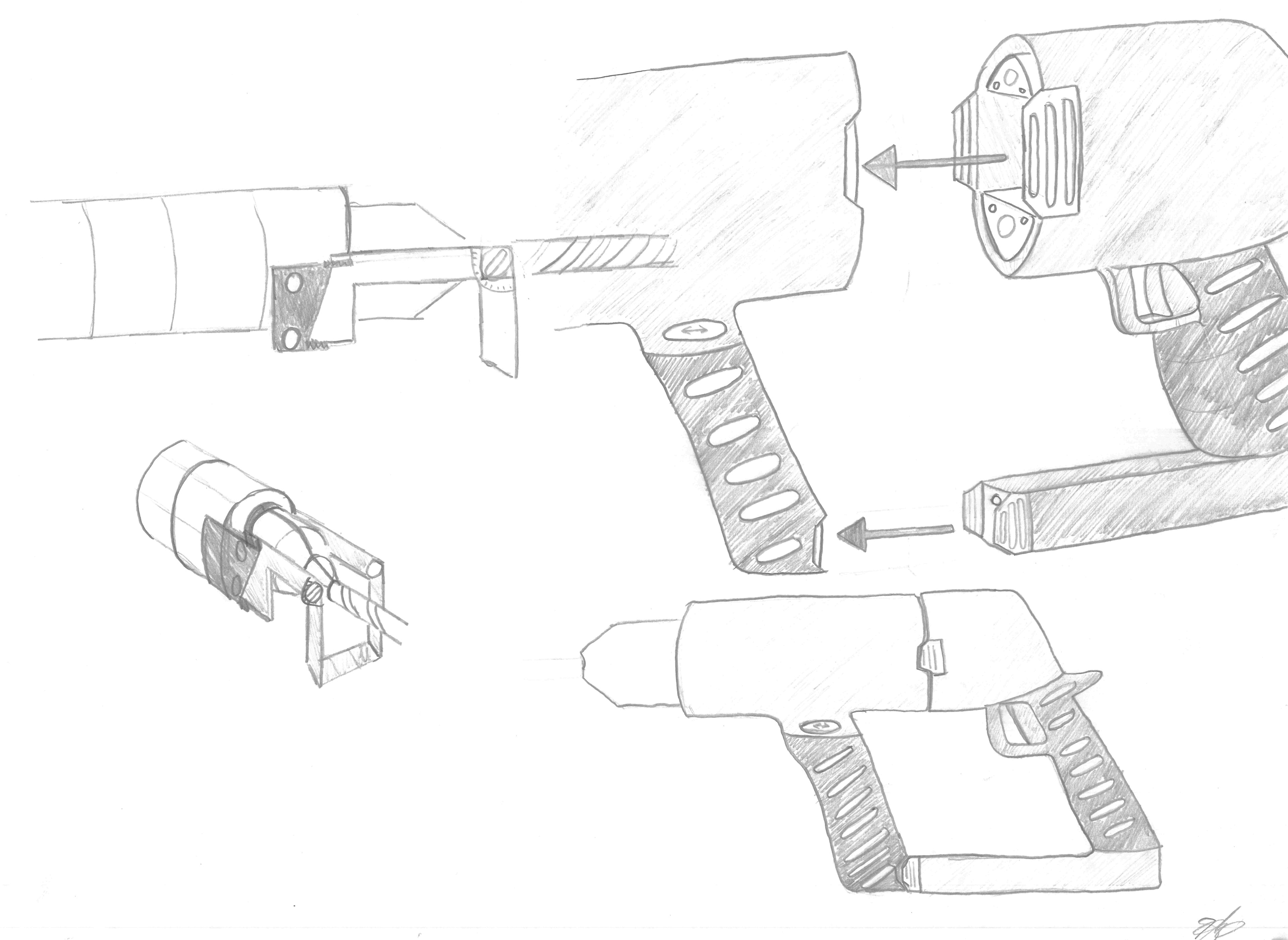

With the generosity of the brief allowing for a more speculative type of design. The conventional layout and form of a drill was challenged and this included the relocation of the battery as well as its form, a reciprocating saw type of design and a built in depth guage or 'fence'.

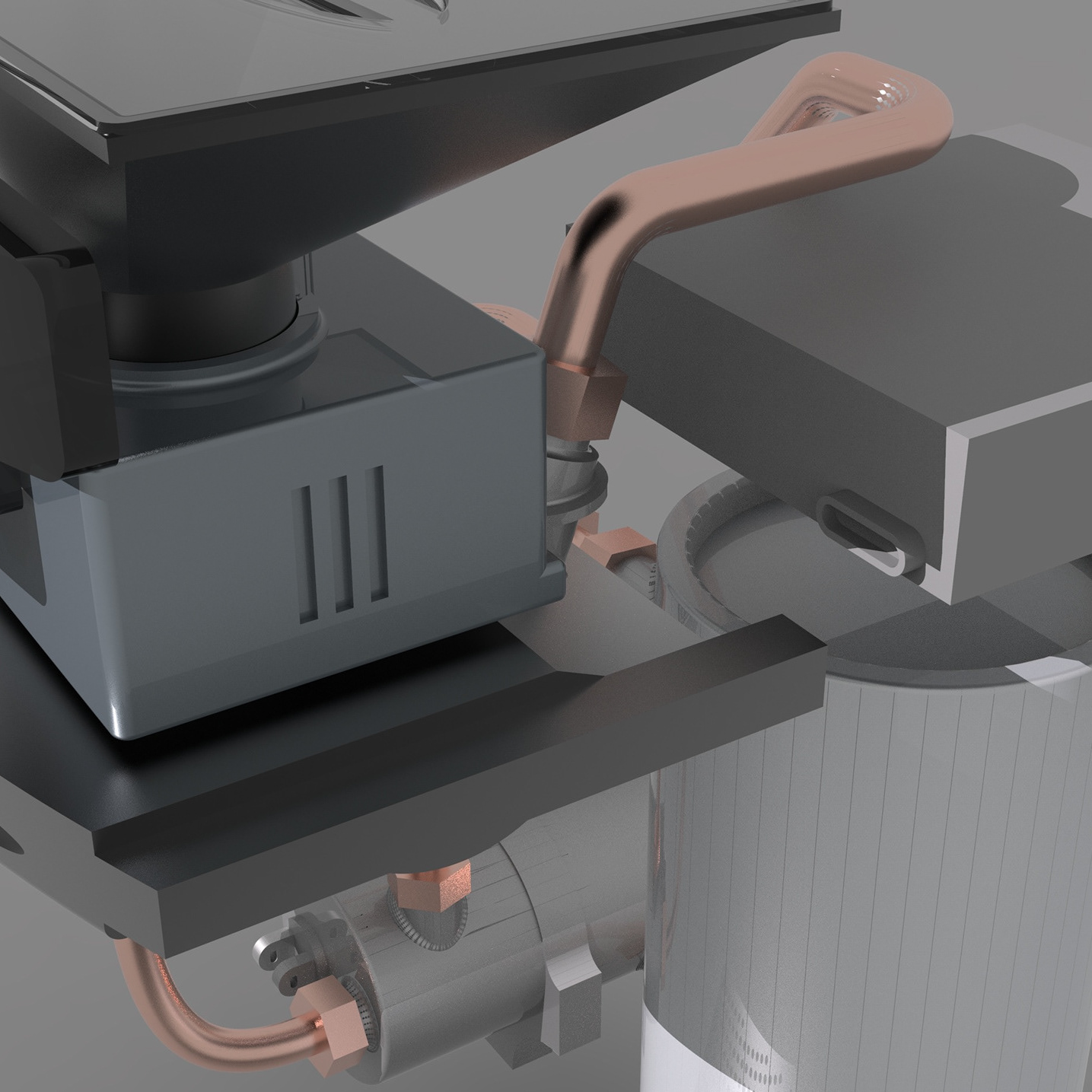

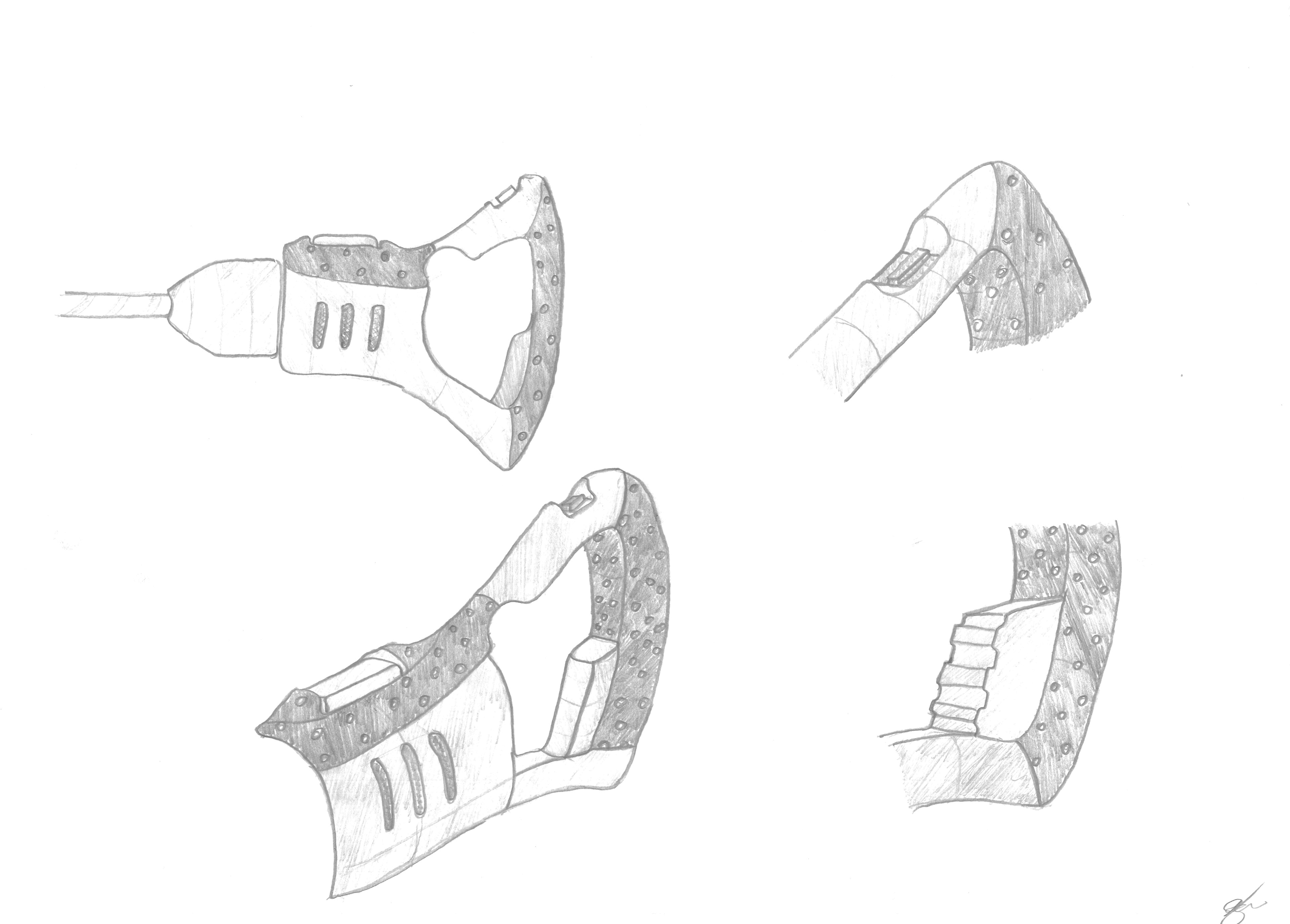

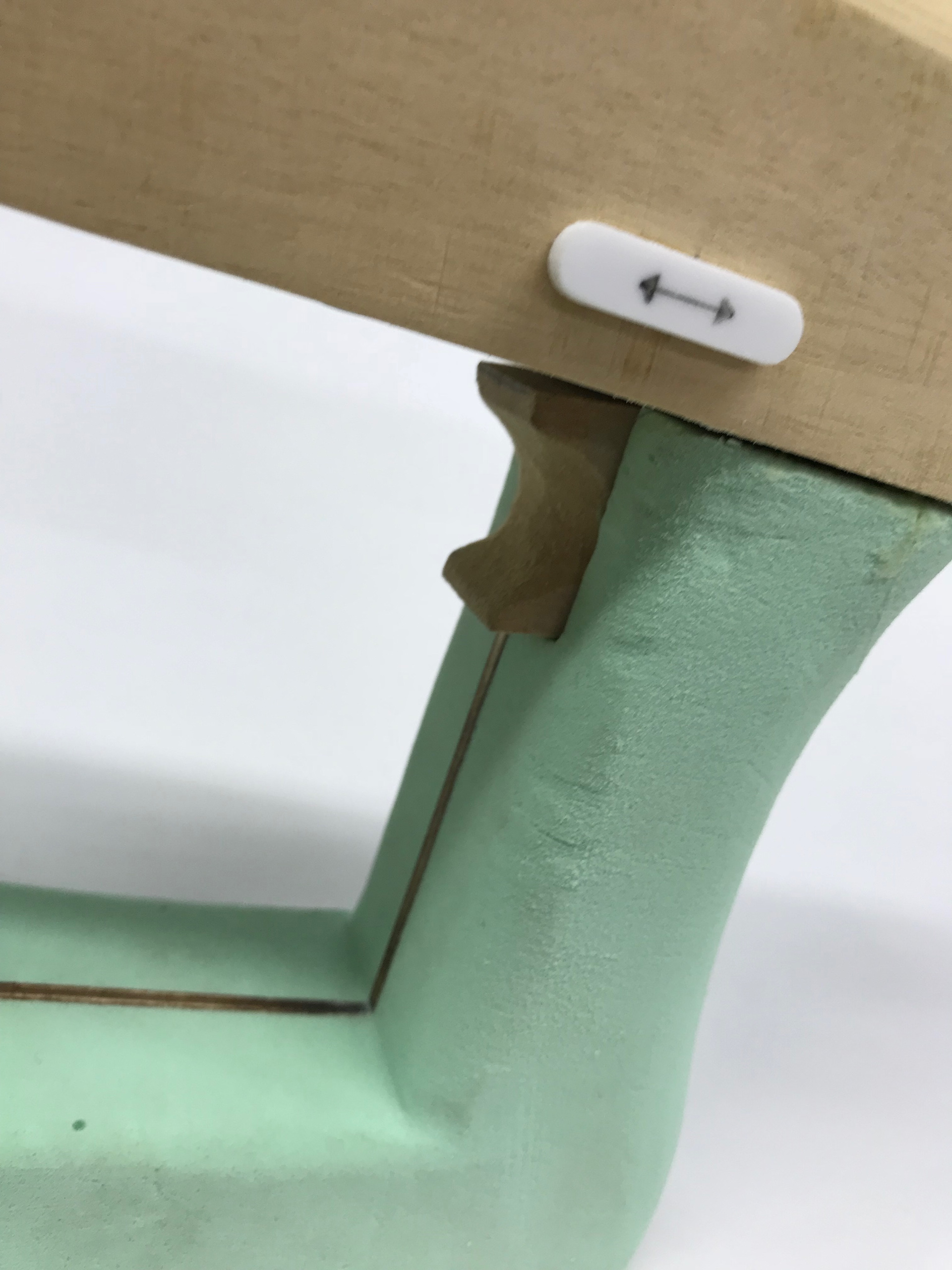

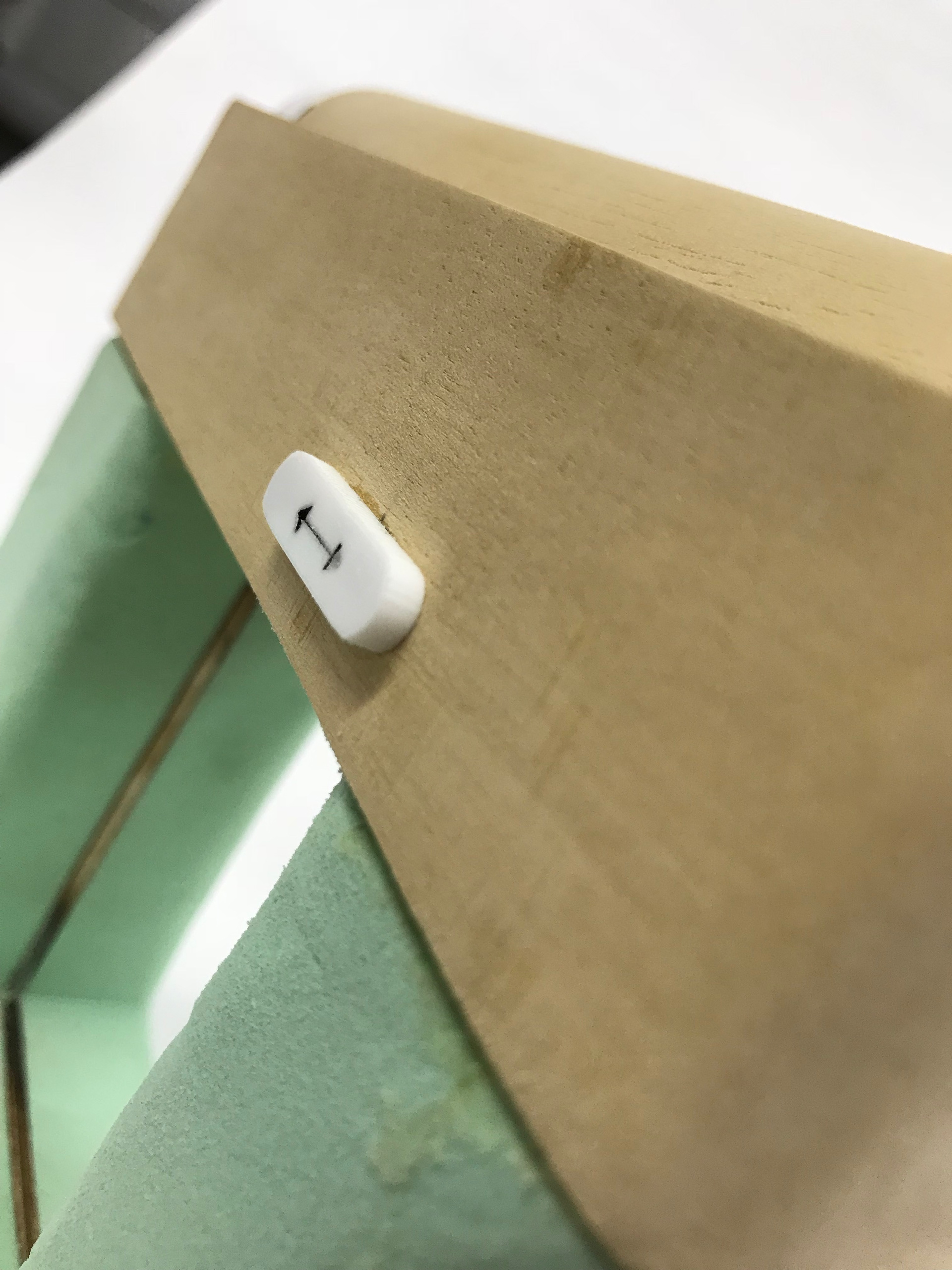

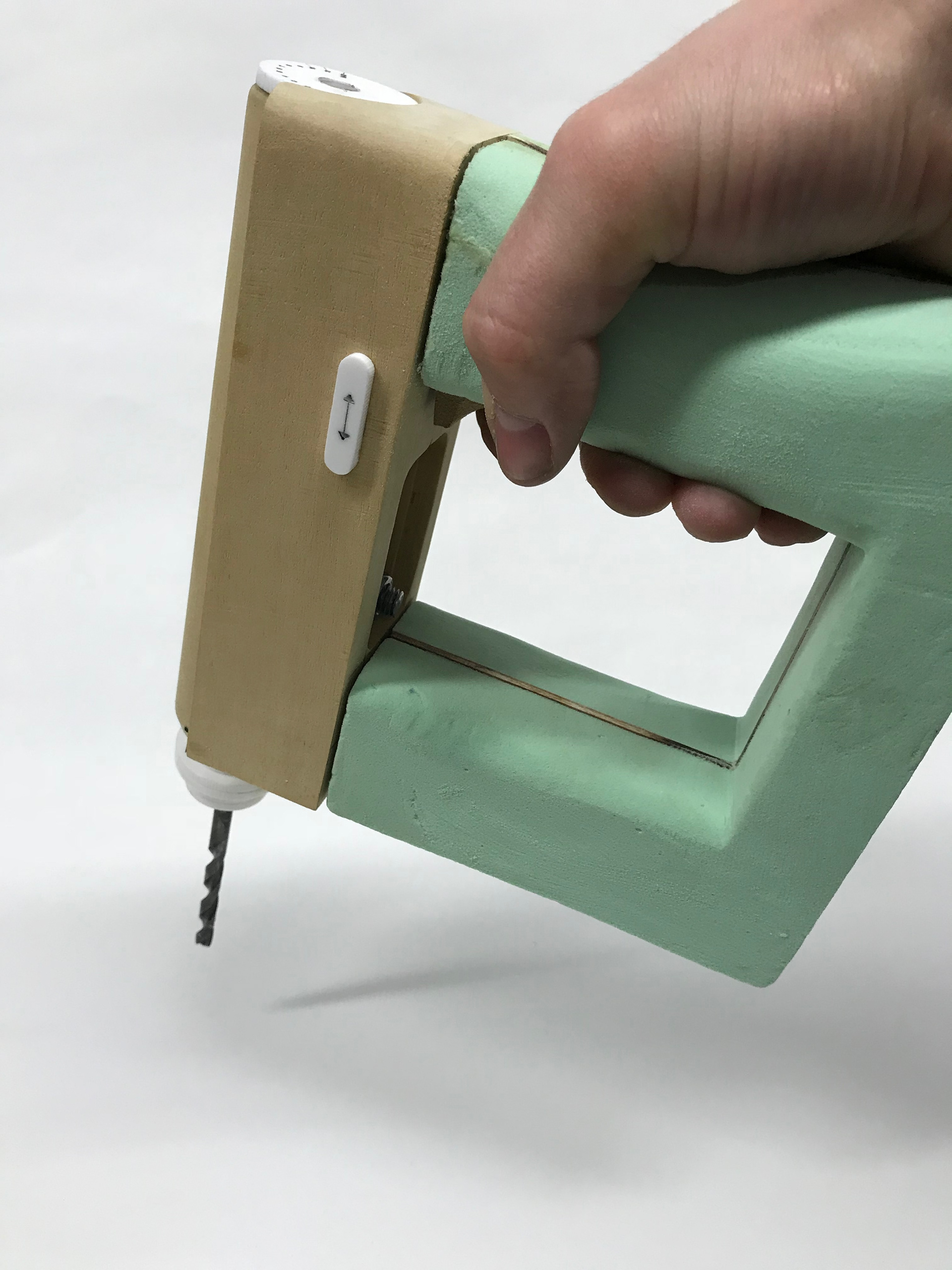

A series of 4 foam prototype models were made as the ergomomic features were dictated by overall feel. The design of the fence was incorporated into the design due to electricians requiring these to install wall gromits as well as when drilling to sensitive wall cavity's and this idea was put into fruition by speaking to two local based Sheffield electricians. The overall location of the functional touch points did not change due to their optimisation.

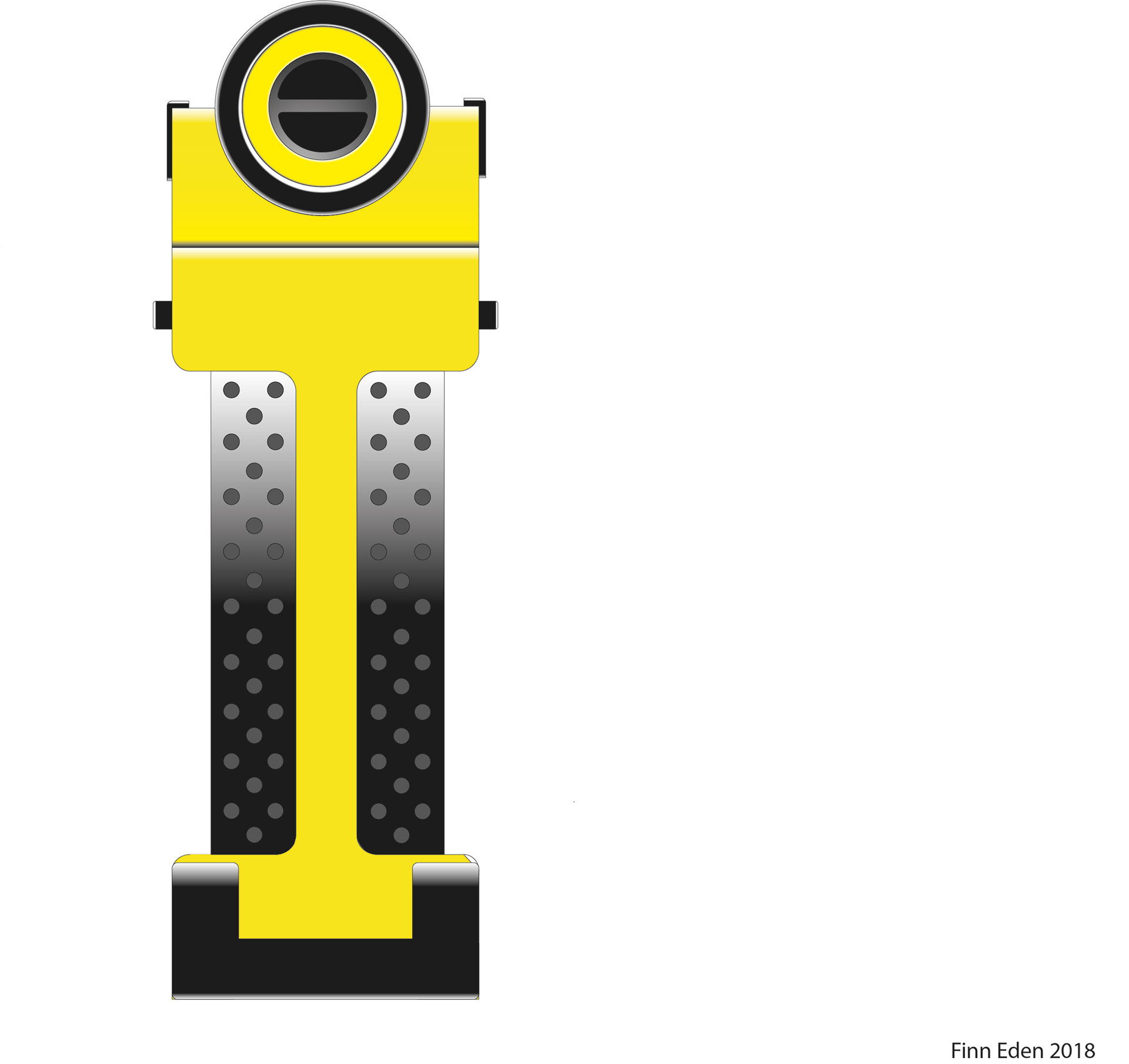

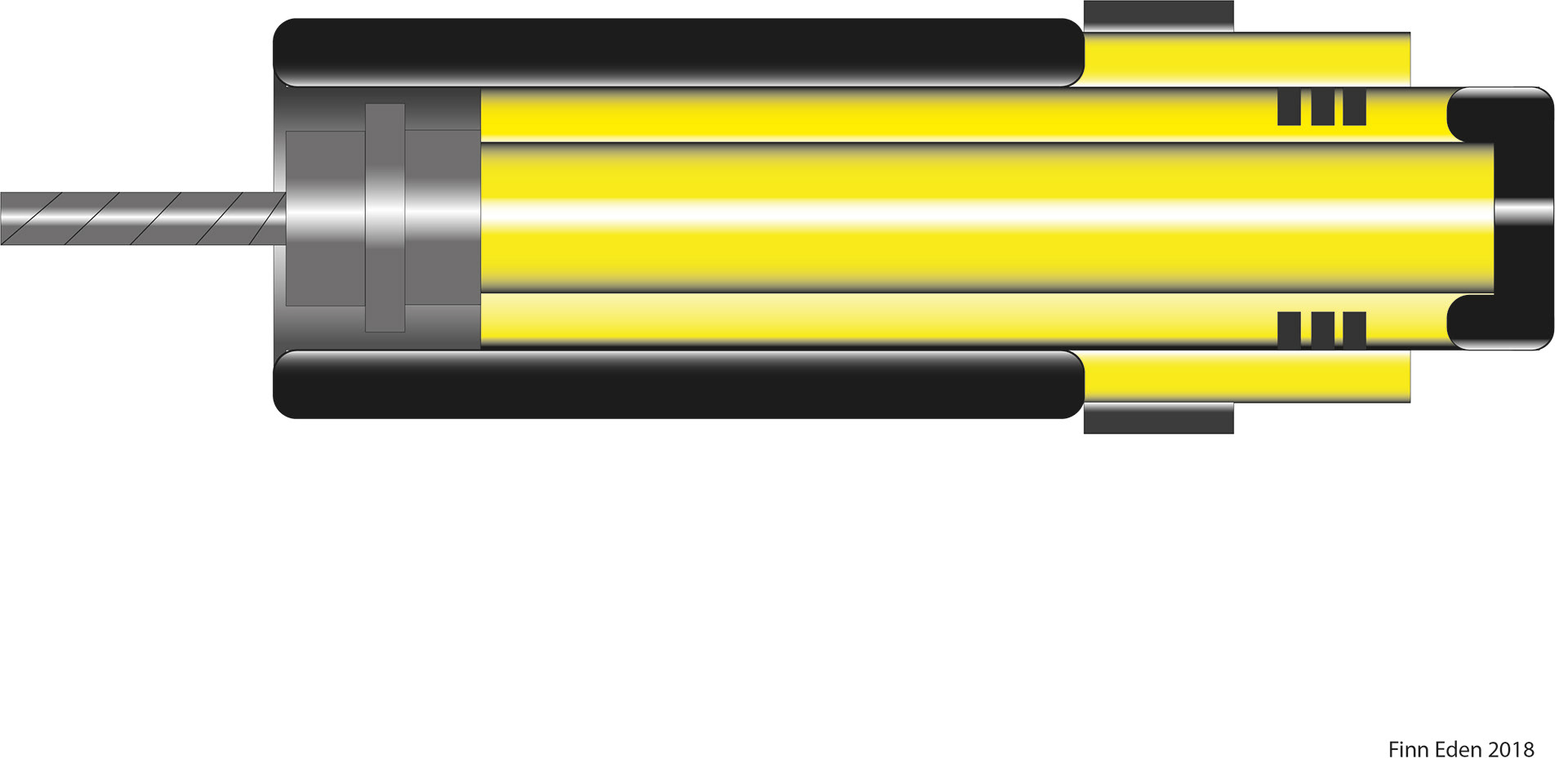

A final model was made and this could demonstrate the overall compact size of the drill which aided it's manouvreablity. All of the direction and trigger switches could be accessed with ease and the speed control being accessed on the top side of the barrell assembly. The fence itself could be easily operated with using the corresponding markings.

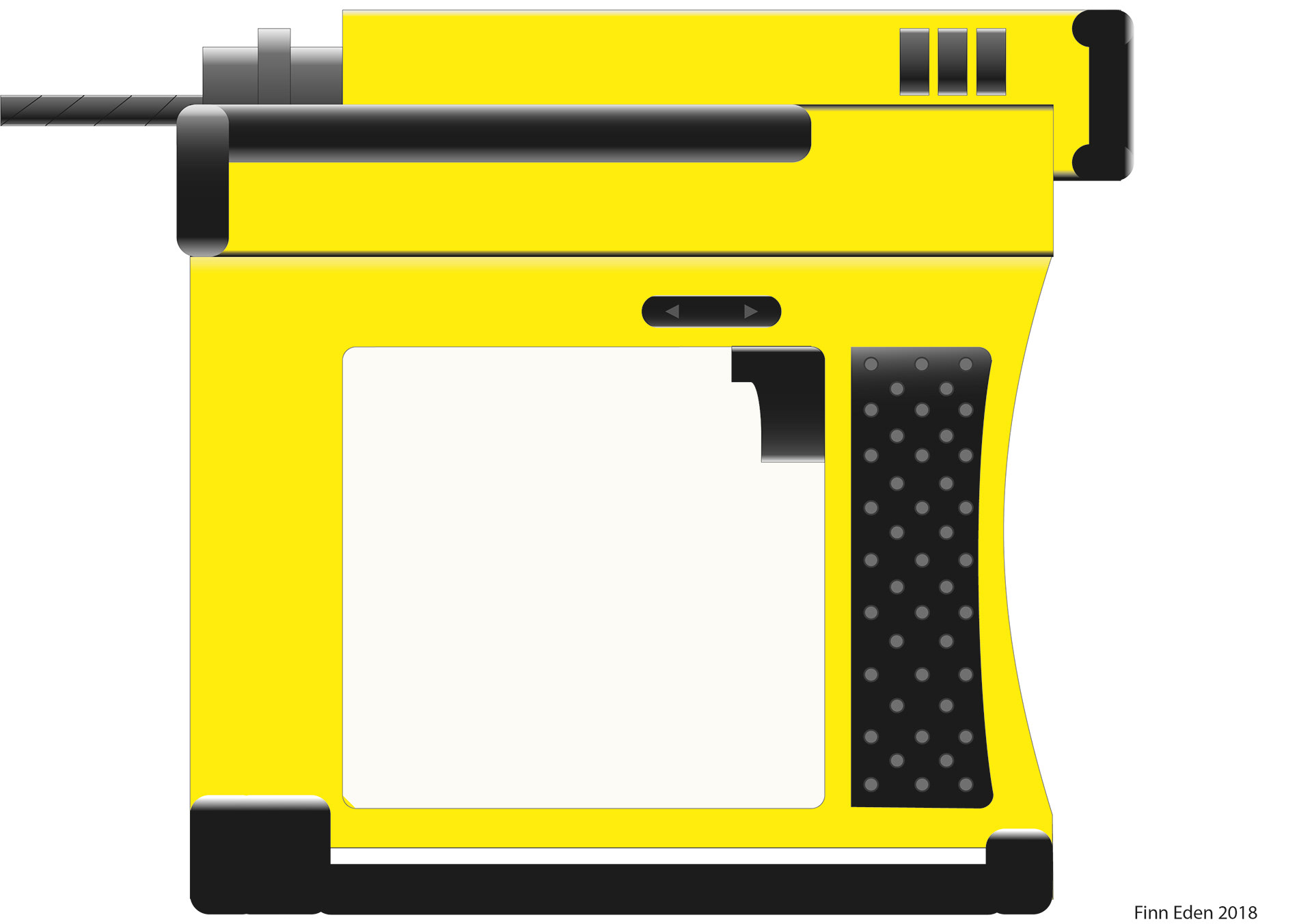

As to meet the requirements set out in the brief. A series of 2D renders had to be made in Adobe Illustrator to conceptualise the design in the real world. It was chosen that the design language of the American Tool Maker DeWalt. This fitted the design rather well with all the touchpoints contrasting in black to the main bodyside colour of yellow.

Summary of Key Skills Used in This Project:

Reverse engineering, User Analysis, Prototyping informed by ergonomic design, Ideation through sketching using existing forms, Use of Adobe Suite to create 2D renders.